by Eric Meier

“What’s the best type of wood finish to use for this wood?” I’m always amused when I get asked this question, as if there is only one single “right” finish to use for a given wood species. The real answer would be, “it depends…” It all depends on what type of look you’re going for, what level of protection you want, how much maintenance you’re willing to do, etc.

But the more I think about this question, the more I realize that although there is no “wrong” finish for a given wood species, there are definitely some finishes that seem to work better in certain situations than others. It all depends on context. With this in mind, the following is an overview of a number of consumer-level wood finishes, as well as my honest assessment as to which ones work best, and when.

Rub-in oils

The Lowdown: These are more or less pure oils, and they are extremely simple to apply: you just rub them in, wait a few minutes (or hours) to allow the oil to penetrate the wood, and then wipe off the excess. The two main players in this category are tung oil and linseed oil. Given enough time, both will naturally dry or cure on their own. (As opposed to other natural oils—think canola or olive oil—which just stay “wet” for an indefinite period of time and would eventually go rancid.)

Quartersawn White Oak box finished with boiled linseed oil

Boiled linseed oil (BLO) tends to be the cheaper of these two oils, and since raw linseed oil can take a very long time to dry, heavy-metal driers (cobalt/manganese salts) are added to accelerate the curing process in lieu of actually “boiling” the oil. For something closer to a true boiled linseed oil without the added chemicals, try something like Tried & True Original Wood Finish, which is FDA approved for direct food contact in both its cured and uncured state.

Tung oil is very similar, except that raw tung oil still eventually dries and can be used as-is. (Look for words such as “raw,” “pure,” or “100%” in the name to find the straight oil.) There are also heated/altered versions of tung oil which, like linseed oil, helps the oil polymerize (fancy chemistry word for “dry”) faster. Many “tung oil” finishes sold on the market today are not truly pure tung oil, but may incorporate a portion of tung oil with other resins and could really be considered an oil-varnish blend, discussed further down.

Where it works: These oils give a rich warmth to the wood surface, and linseed oil in particular tends to accelerate and exaggerate the natural patina of the wood. They tend to impart a satiny sheen that isn’t too glossy, replicating a “natural” wood look. However, because it’s in the wood rather than on it, these oils don’t offer the best protection and wear/moisture resistance, and should be used on places that receive minimal wear, or on pieces where fresh coats of oil can easily be reapplied.

Best Bets: Walnut, mahogany, oak, cherry (if you’re looking for a darker, richer natural patina with low sheen).

Fails: Anywhere a glossy, high-sheen finish is desired, or any place where wear/durability will be an issue. Also, linseed oil isn’t the best for woods like padauk, purpleheart, or cocobolo (if you like the color of the wood as-is, this isn’t the finish to use; light-colored woods will yellow, and colorful woods age/darken much faster).

Oil-varnish blends

The Lowdown: Oil-varnish blends are an extremely popular wood finish. They combine the ease-of-application of rub-in oils, but are fortified with resins to give them a bit more durability. Various other additives may be found as well, such as dyes/pigments, driers, or UV inhibitors. Depending on the composition of the blend, it may be more able to build up a moderate sheen (semi-gloss) on the wood surface.

One of the biggest drawbacks to these sorts of finishes is that they are somewhat of a mystery in terms of their composition. In nearly all cases, they will use a linseed or tung oil base, but beyond that, there’s no telling what exactly is in each product. Many times, a host of products are cleverly named as a marketing ploy to increase sales (e.g., “teak oil” for Teak furniture, “antique oil” for antique furniture, etc.) At times, an oil product may be nothing more than a drastically thinned-down version of a pure rub-in oil with added driers to make it easier to recoat in less time.

Where it works: In most instances, oil-varnish blends work in much the same way and in much the same capacity as rub-in oils. They soak into the wood and provide a thin, natural-looking finish that’s easy to apply. They may have a bit more versatility in terms of sheen and color options. Durability of the finish is slightly better than pure oils (due to added resins), but is usually still inadequate for high-traffic, high-wear pieces.

Best Bets: [Same as rub-in oils] walnut, mahogany, oak, cherry (if you’re looking for a darker, richer natural patina with low to mid sheen).

Fails: [same as rub-in oils] Anywhere a glossy, high-sheen finished is desired, or any place where wear/durability will be an issue. Also, linseed oil-based finishes aren’t the best for woods like padauk, purpleheart, or cocobolo (if you like the color of the wood as-is, this isn’t the finish to use; light-colored woods will yellow, and colorful woods age/darken much faster).

Varnishes

The Lowdown: Varnishes are known for their durability and toughness. A variety of sheens are available: from satin to glossy. They are generally oil-based, and contain synthetic resins such as phenolic, alkyd, and urethane.

The most desirable attribute of varnishes is that they are able to build up multiple coats (known as “film-building”), which enable them to excel at truly protecting the wood. When slopped on with a brush in several thick coats, they’re notorious for creating a plastic-like appearance on wood surfaces. Thinned-down formulations also exist, which can be wiped on, but still require slightly more care to apply than a strictly rub-in oil finish.

What sets varnishes apart from one another is their formulation and quantity of resins. Finishes that contain a higher percentage of oils and less resins are called long-oil varnishes, and tend to be more elastic and soft—perfect for outdoor applications and areas that receive a lot of moisture (Epifanes is a good example of a long-oil varnish). Toward the other end of the spectrum are medium and short-oil varnishes, which contain a higher concentration of resins and cure to a harder finish—good for table tops and floors (such as Behlen’s Rockhard Table Top Varnish).

Where it works: Anywhere toughness is paramount, varnishes should be your go-to option. Also, the glossy properties of varnish, when applied well, can give an eye-catching sophistication to a piece.

Best Bets: Exterior wood surfaces (boats, decks, outdoor furniture), as well as high wear areas (flooring, tabletops, and cabinets). Teak, white oak, cherry (use water-based varnishes such as Minwax’s Polycrylic to preserve lighter colored woods such as maple).

Fails: Oily tropical hardwoods (can have issues curing properly), as well as any project where a natural or rustic look is desired. Wormy chestnut, ambrosia maple, banksia pods.

Evaporative finishes

The Lowdown: The two primary types of evaporative finishes seen today are shellac and lacquer; they’re a bit different than varnishes or oils as they are composed of a solvent and a resin, and simply rely on the solvent to evaporate, leaving the resin behind. Shellac uses a denatured alcohol (DNA) solvent with a natural resin—secreted by lac bugs found in India and Thailand. Lacquer uses a special blend of solvents referred to simply as lacquer thinner, with alkyd and nitrocellulose resins. Because they rely on evaporation (rather than oxidation), they both tend to be very fast-drying. Like varnishes, they are film-building and sit on top (not in) the wood, and are available in a number of different sheens. They offer better protection than oil or oil-varnish blends, but fall short of the supreme toughness of varnishes.

One of shellac’s claims to fame is its compatibility with a variety of surfaces and topcoats. The old adage is: shellac sticks to everything, and everything sticks to shellac. Traditionally, shellac is mixed from shellac flakes dissolved in alcohol, but premixed commercial varieties are also available. The downside to this is that shellac has a somewhat short shelf-life (about one year from the time it’s mixed). Instructions on mixing your own shellac are given in my page on finishing exotic woods. Zinsser’s SealCoat is an excellent shellac product that is premixed and relatively shelf-stable.

Bonus note on shellac: Based on an experiment of wood finishes for African padauk put on by Woodworker’s Source, it was found that shellac outperformed all other major finish types in preserving the orange color of the padauk. My theory as to why this is the case is that padauk’s colors (as well as many other exotics) are very much soluble in alcohol, and the solvent present in the shellac may actually be pulling some of the wood’s natural colors out of the wood surface and locking them into the lac resin.

Lacquer tends to be a little tougher and more resilient than shellac. Many professional furniture makers have dedicated spray booths and spray lacquer onto their pieces with great efficiency. But even without expensive spray equipment, much of the benefits of lacquer can still be reaped in the form of brushing lacquer, as well as spray-cans of lacquer sold at hardware stores. Besides the somewhat noxious solvents contained in lacquer, the only other downside is that the nitrocellulose resin (contained in ordinary lacquer) tends to yellow with age, which may be an issue on lighter-colored woods. A special type of lacquer—cellulose acetate butyrate (or CAB)—made with different, non-yellowing resins is also available.

Where it works: Great for interior projects that will see a moderate amount of use (again, varnishes should be used for the most demanding applications). Choose an evaporative finish if you have a very colorful or ornately figured project that you want to highlight in all its glossy glory. Some of the most dazzling and renowned wood finishes in the world have historically been from padding very thin coats of shellac onto the surface of the wood (a technique called french polishing) until an immaculately clear shine emerges.

Best Bets: Rosewoods, colorful exotics (padauk, purpleheart, bloodwood, cocobolo), and burls.

Fails: Evaporative finishes tend to have poor heat and chemical resistance (its own solvent is capable of re-dissolving the cured finish), and should be restricted to interior projects. Shellac really only comes as a glossy finish, and must be rubbed out by hand to a lower sheen (using #0000 steel wool

) if a satiny finish is desired.

Fill, Level, and Buff for the Win!

The Lowdown: With all film building finishes (polyurethane, tabletop varnish, shellac, and lacquer), there’s just a few critical elements missing from achieving a flawless, glass-like surface. The first is the pores of the wood. Some woods have small enough pores that it doesn’t matter (maple, cherry, beech, boxwood, holly, and poplar), which are sometimes referred to as close-grained woods. But many other woods have larger pores that the finish will sink into, creating unevenness in the finish film, and ruining the smooth-as-glass effect. These open-pored or open-grained woods include a bunch of common favorites, as well as many exotics, such as: oak, walnut, mahogany, ash, sapele, purpleheart, zebrawood, bubinga, teak, cocobolo, and so forth.

The foundation to every mirror-like gloss finish is an underlying smooth wood surface. It is absolutely critical with open-grained woods that the pores be filled in order to obtain a smooth wood surface before any finish is even applied to the wood. For natural colored woods (in varying shades of brown), an oil-based pore filler can be used. (I greatly prefer oil-based fillers over water-based products because they have less of a tendency to shrink back into the pores over time, material won’t come out of the pores during sanding, and they generally fill the pores in a single application.) These fillers can also be stained to roughly match the color of the wood being filled. With multi-colored woods (such as zebrawood) or colorful woods (like padauk), a transparent grain filler should be used. I prefer spreading a thin layer of thick CA glue over the wood surface with an old credit card or playing card (using a fan for ventilation), spraying accelerator, and then sanding the surface flat with 200 – 300 grit sandpaper.

Besides the pores, the second obstacle standing in the way of achieving a glassy wood surface is minor imperfections. No matter how perfectly a finish is brushed, sprayed, or wiped on, there will always be imperfections in the final topcoat. These make a bigger difference than you may realize. Dust, drips, unevenness, brush hair, lint, haze, and a host of other imperfections mar the work of even the most assiduous of laborers. The finish will need to be leveled with fine-grit sandpaper, and then buffed up to the desired sheen. Leveling should be done carefully with 200 – 600 grit sandpaper. Because of the risk of sanding through to raw wood, most finishers that intend to level a finish will intentionally build up a thicker film to have a greater margin of error. For spray lacquer, the norm seems to be about 10 coats—brushed finishes should generally require slightly less than that.

Once the finish has been adequately leveled (the wood surface should be uniformly dull—any glossy/low spots remaining indicate incomplete leveling), you can be assured that every possible imperfection and irregularity has been removed from the finish film. The finish is flat and flawless—with no luster whatsoever. All that’s left is to restore the gloss using very fine sandpaper and buffing compounds. After using normal sandpaper up to about 800 grit, I’ve found that 1000 grit Abralon discs are absolutely fantastic at preparing the finish for the buffing wheel. After the Abralon, I use a cotton buffing wheel with some Menzerna buffing compound applied to the wheels to bring the finish up to a candy-like shine.

Where it works: Fine woodworking. Anywhere that you’d like to show off the details of your wood projects with a new-car-paint level of shine.

Best Bets: Just about anything with an interesting grain or color. walnut, oak, mahogany, cocobolo, rosewoods, snakewood, and so forth.

Fails: Outdoor projects (mother nature will laugh at all your efforts and subsequently trash your hard work in short order). Carved or irregular objects can be very tricky if not impossible to level or buff out. Very light or unfigured woods (plain maple, birch, or pine) aren’t flattered much by this technique.

Specialty Finishes

The Lowdown: In certain circumstances, you may want/need to use a specialty wood finish that doesn’t quite fit the characteristics of any of the above categories.

One product that is very similar to the pure oils such as tung or linseed is mineral oil. Mineral oil doesn’t cure (polymerize), nor does it go rancid. It just sort of “is.” And for a butcher block or other food utensil, that’s okay. The idea is that this harmless, innocuous substance penetrates the wood and remains there, helping to drive out moisture and preventing bacteria from getting lodged within the wood and breeding. Mineral oil just stays somewhat “wet” and needs to be recharged and replenished from time to time.

Although an adhesive, CA glue can also be used as an actual finish for small turned items. Thick CA glue is applied to the piece via a paper towel with the lathe on a slow speed. The glue is then allowed to dry (or sprayed with an activator) and then sanded with very fine grit sandpaper. This process is repeated until a sufficiently thick finish has been formed, and then it is leveled and buffed in much the same way as any other film finish. The resulting finish is very hard, strong, and long-lasting.

Finally, there is paste wax. In most cases, wax should be seen as a temporary finish. It’s generally used in new projects to add an extra layer of protection to the wood after the final finish has been applied and buffed. In older projects and restorations, it’s used to bring back some of the shine of a piece’s younger days, and to help mask and scratches or imperfections in the wood. But with all of waxes’ cosmetic improvements to a wood surface, it should be remembered that wax will eventually rub off with wear. (Also keep in mind that despite any marketing pitches, wood does not “need” wax. Wood is not “thirsty.” Wood reaches an equilibrium moisture content with the surrounding air based on the relative humidity of the environment.)

See also:

Are you an aspiring wood nerd?

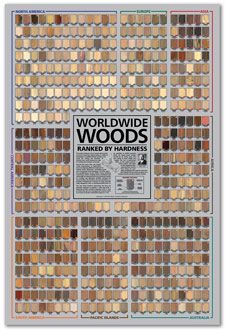

The poster, Worldwide Woods, Ranked by Hardness, should be required reading for anyone enrolled in the school of wood nerdery. I have amassed over 500 wood species on a single poster, arranged into eight major geographic regions, with each wood sorted and ranked according to its Janka hardness. Each wood has been meticulously documented and photographed, listed with its Janka hardness value (in lbf) and geographic and global hardness rankings. Consider this: the venerable red oak (Quercus rubra) sits at only #33 in North America and #278 worldwide for hardness! Aspiring wood nerds be advised: your syllabus may be calling for Worldwide Woods as part of your next assignment!

The poster, Worldwide Woods, Ranked by Hardness, should be required reading for anyone enrolled in the school of wood nerdery. I have amassed over 500 wood species on a single poster, arranged into eight major geographic regions, with each wood sorted and ranked according to its Janka hardness. Each wood has been meticulously documented and photographed, listed with its Janka hardness value (in lbf) and geographic and global hardness rankings. Consider this: the venerable red oak (Quercus rubra) sits at only #33 in North America and #278 worldwide for hardness! Aspiring wood nerds be advised: your syllabus may be calling for Worldwide Woods as part of your next assignment!

We just had 2 Oak windows installed that need finishing. These are South facing windows located in Arizona. The windows are on each side of the wood burning fireplace. The whole house has stained trim and stained doors. I will not ask you the best way to finish a window but, I will ask you if applying a varnish over a dye will have the same affect as a stain over a dye? I’m also looking to the future with regards to sanding, finish removal, etc. when it comes time to refinish. Can it be spruced up easily without a… Read more »

I will be drying walnut slabs that had some live termites and dry rot. However, most of the wood is solid and beautiful. I want to treat with timbor mixed with ethylene glycol- or perhaps another glycol to encourage penetration of the borate. I’m NOT going to buy boracare, it’s very expensive and its essentially timbor mix with ethylene glycol.

I’ve been finding a great deal of contradictory information about the effect borates and glycols have on wood finishes and epoxy treatments. Does anyone have experience finishing wood after glycol/borate treatments? What kind of issues can I anticipate?

Thank you for all the information! I recently finished a bench with a cypress top and haven’t found a straight answer on what finish to use. Preferably, I would like for the piece to remain inside and still have a natural look to it. If you have any recommendations on a finish, that would be extremely helpful!

Thanks!

I have read this article twice… Love the depth of info and have also bookmarked it too! We have a new front door made of fir. 3/4 of it is a window in a prairie 9 lite design. It will be on the North side of a southern Virginia house and there is no storm door. So no direct sun but being in shade means it can stay humid and damp. I will be finishing the door once the contractor installs it. He is advising us to paint the door but I grew up in the woods of New England… Read more »

For an exterior application like this, you really should try to protect the wood, which was why the paint was suggested. The protection comes in the thickness of the film. Wood finishes can be built up in a similar way too. The problem is that if you try to built up a bunch of coats of something like epifanes in a matte finish, you will loose a lot of clarity because of the thickness of the film. Although not entirely economical, you might consider building up coats of gloss finish and then do a final topcoat with a matte finish… Read more »

Hi friends, I’ve made my first “big” piece of furniture, a bed (for myself and girlfriend) of american walnut wood, part solid wood, part veneered plywood. My father has a furniture factory, although I’m not working in wood world, electrician here. The bed looks good, as I wanted, but now I’m not sure on how to finish it and my father only sells furniture in raw condition, he knows nothing about varnishing. Also, this is the first piece on walnut wood in his factory. I want a natural look of the wood, no dyeing, no too much shine. It will… Read more »

While professional tools and products produce excellent results, one of the main things that those tools are gear toward is speed. Time is money, and in a lot of larger scale operations, they just don’t have the time to hand apply a finish, so they spray it on. It’s fast and gives excellent results. But if you don’t have money, you probably have time. If it’s important to you, you should practice a finish technique on a smaller piece of scrap walnut and get it exactly how you want it before even touching the finished piece. If you have time… Read more »

I’m putting down new pine floors. I’ve heard conflicting advice. One person advised to use polyurethane, as it’s harder and more protective. Another, said a rub in oil, like tung, or linseed, would be best Or, Danish oil. Their reasoning was that, because pine is so soft the wood will dent and scratch, and therefore the floors will need refinishing sooner. So, polyurethane would be a poor choice as you can’t really spot repair they felt. I have children, so scratches, bumps, etc are inevitable. I don’t mind a rustic look, but the pine is new, so will at first… Read more »

Unless it is for a cabin or you are intentionally wanting a rustic look, I would recommend using a high-performance finish meant specifically for floors (i.e., not a rub in type oil). I understand the rationale because of the softer wood used, but this generally only applies to dents and deep gouges (which you wouldn’t really be spot repairing anyway). There is an incredible benefit to using a high quality finish, even on softer woods. A lot of wear and tears comes from abrasions and applications where the wood hardness doesn’t really come into play. (Think of dragging a couch… Read more »

I cannot find a credible answer to this question anywhere, so if you have experience with this, I’d be grateful to hear from you. Will outdoor wood turn gray (eventually) after treatment with boiled linseed oil? BTW, gray is the desired outcome. Many thanks.

In time, yes, it will turn gray.

We recently had some trees thinned and cut down and I thought this one was beautiful. I have sanded the tops of these two slices and hope to put some feet on them then place them side by side with a glass top for a coffee table. I love the colors and the different veins in the wood. What would be best the best oil (?) to use — they dont need to be waterproof or hard wearing, I just want to bring out and maintain the natural colors of the wood. Any suggestions would be greatly appreciated!

You could probably just use boiled linseed oil. Just keep in mind that the endgrain color will more than likely darken substantially when a finish is applied.

Having a professional wood finishing business for residential and commercial properties, I struggle trying to get clients to understand the differences in wood finishing products and effect it has. Of course the type of of wood has a tremendous effect on the finished look well as the degree of finishing. I wanted to thank you for posting this very comprehensive content on wood finishing. I have bookmarked this and have already begun to share with new prospective clients that are struggling with what they want. This is definitely a resource to help them sort through a world of wood finishing… Read more »

I recently stripped this dresser which has a number of veneers on it. I’m contemplating using either Sutherland Welles Wiping Varnish Low Lustre or Osmo Polyx-Oil Matte/Satin to finish the dresser. I’m concerned about what might disrupt the attached veneers and also to get the best most natural looking appearance.

I’ve researched this so much and read too many opinions; but I’m more than willing to listen to one more.

Thanks.

Looks like a lovely piece. My only advice would be to not experiment on it directly if you can at all help it. Either try a proposed finish in an inconspicuous place first, or try to find a test piece or two that closely mimics the piece itself, and see how you fare.

Hi Eric, I am interested to know if tung oil would work on this Mexican pine table and chairs as I would love to buy them and have a go at beautifying them. Thank you so much. Ana

Hi Eric

I recently purchased a dining room table that was split when it arrived. I already received my refund and rather than buying a new one, I decided to try and fix it. I’m almost done, just need to identify the right stain, oil, varnish, etc to try and match the color. I’ve tried a few different stains on the underside and I’m starting to think it actually has a varnish or shellac.

The color is only on the top coat.

Ive attached a photo. Do you have any recommendations or ticks to figure this out?

Thanks,

Andrew

Hi Eric, I just bought a small dining table and a set of stools, both made with solid mango wood with a chestnut finish, but from different manufacturers. The table has a gorgeous, reddish, fairly glossy finish and amazing, beautiful wood grain. The stools are more of a matte finish, and a less reddish tone. I’d like to at least give the stools a semi gloss look, and if I could also add a bit of reddish tone that would be ideal but not an absolute requirement. How would you recommend achieving the semi gloss appearance for the stools, and… Read more »

When the colorant is in the finish, instead of applied to the wood itself, it’s generally called a “toner”. One example of a toner-type wood finish that’s commonly available to consumers is called “polyshades” I think from Minwax. The quickest thing you might try is to apply a glossier polyshade product right over top the existing finish. However, I think you’d get slightly better results if you sanded away some of the existing finish. If you try to add an orangish red color on top of an already medium brown finish, it may end up looking darker than expected, and… Read more »

I have three large pieces of indoor furniture that I was told is acacia wood. I like the raw wood look and color on the outside but fear it’s too dry. What should I be using and how often?

The wood can’t get “too dry” — it simply reaches an equilibrium moisture content based on the relative humidity of the surrounding air. This usually happens within a few days or weeks.

Thank you, that is reassuring. Would danish oil be the best option for the longevity of the acacia wood?

I have several indoor projects for which I’m using a smooth red cedar (shelf, barn door, laundry room shelving). I’m not concerned about damage so a hard finish isn’t needed, and I’m ambivalent about keeping the cedar smell so I just want a finish that will bring out the “wet look” and make the natural colors pop. Is mineral oil my best bet or do have a better recommendation?

I wouldn’t use mineral oil as it’s generally kind of a mess to use and doesn’t really ever dry. If by “wet look” you mean literally just darker color (as if the wood were wet) then I’d use something like a simple boiled linseed oil, cheap and simple, gets the job done. If by wet look you mean like a glossy finish that’s shiny, you might try something like shellac or lacquer, or maybe some cheap glossy polyurethane.

I’m trying to identify the wood species of my front door (below is a link to some pictures). Some pictures are closeups of the wood grain. I’ve been told the wood is a combination of Fir with Pine in the panels, or Red Oak Let me know what you think.

https://photos.app.goo.gl/M8a9Xg8YgVBGTEz87

What product would you recommend to treat/stain the door.

Thanks,

Curtis

I see resin canals on the face grain of the first picture, which strongly suggests a species of pine. Can’t say much about the rest other that it appears to be a softwood (possibly fir). Definitely not oak. You might try a gel stain to get a more even color with the softwoods.

Thank you Eric for your expert analysis and recommendations.

I made a shelf from birch with strip of walnut down middle; how cani finish to look the best

Hi

I am a wood enthusiast and I have some wood samples that I would like to prepare to exam myself. How can I prepare the end grain to see the wood anatomy? any recommendations

My process is to take a very fine cut with a miter saw, just barely shaving off a tiny bit of wood. Then diligently sand through the grits, from about 220 up to around 800 for normal sandpaper. Then I use special cushioned abrasives such as Abralon pads to go to 1000 or 2000 grit for maximum clarity, but that might be overkill for your application.

Another view

I can’t tell, the pictures are very small and too far away. Sorry!

help! I’m trying to identify this wood or find so,etching similar to stain in a similar “matching” color! It’s shown here in different light settings. Can you help?

Any experience with Rubio Monocoat or OSMO Poly-X? It would be nice to see an in-depth look like the sections in the article above :-)

Hello, I am trying to make a massager for my mom. I need a finish that will not absorb the different essential oils and massage oils that she likes to use, and can be wiped off after each use. It also needs to be safe for frequent contact with skin. Would you have a suggestion for this? Thanks in advance!

Polyurethane has good chemical resistance.

Lacquer would be my first and only choice . It’s easy to apply, weather you spray it or use a brushing lacquer. Light coats are all ways better than heavy coats, sand it lightly after your first or second coat till it fells smith and apply one or two more coats, let the first coat or two dry before sanding With 400 grit sandpaper. After the last coat is dry, like after a day or so, if it feels like it has a couple of nibs, use some 600 to 1000 to remove the nibs and use some 0000 steel… Read more »

Hello, I have an old 70s (?) school/college set of drawers under my kitchen counter which I have recklessly started stripping down. The ?varnish is coming off very easily with a water based stripper and the resulting wood is very smooth with seems like a close grain. I’m sponging clean with water then light sanding. The colours of the drawer fronts vary greatly, so maybe different woods. The grain of the darker resembles teak maybe? Ive tested the stripped wood with an oil application (IKEA behandla) and also have liberon tung oil and another “finishing” oil. Im not too bothered… Read more »

Only thing I would recommend is wood bleach, but you’d need to sand it down to clean and completely bare wood. You can pick up two-part wood bleach at most big box hardware stores. Otherwise, all wood finishes will cause a darkening, it’s just the look of the wood when it becomes wet.

I inherited some basswood (Pretty sure it’s basswood, but not positive) sauna benches. I have repurposed the tops into a bench for my kitchen table. I applied three coats of a water based clear coat but the benches are scratching very easily (zipper on the pocket from a pair of shorts). What can I do to treat these benches to protect them from scratching?

I’m very much new to working with wood… although I love the way they turned out

I have a mahogany exterior door, i do not want to stain just finish it. What would be the best way to preserve and seal for longivity. It has afternoon sun that will hit it. I do plan on having a screen door and tinting the glass to alleviate some of the uv rays. And also sanding prep, whatgrit should I sand with for final sand before apply the coat of sealer/varnish/poly? Sanding sealer first then varnish was my first go to, but I wanted some input on a professional opinion. I would also desire a more satin appearance then… Read more »

If it were me, I would build up a few coats with an exterior-grade gloss polyurethane, and then use satin poly for the final top coat. Or if you’re only planning to apply a few coats, you could just use exterior satin urethane finish for everything. More coats mean more durability. However, if you build up a lot of coats with satin, you tend to lose clarity.

My son is completing an outdoor sensory walkway for his eagle project, consisting of 5 2foot by 2 foot sections, each with different natural materials. One section is going to have tree rounds. What is the best finish to put on the tree rounds to preserve them as long as possible? Anything we should do to help prevent cracking/splitting? Thanks for your help.

Here’s one possible solution that came to my mind: https://youtu.be/b_NTknCCtGE?t=287

Tree rounds are guaranteed to split outside. The only treatment possible would be long immersion in polyethylene glycol and I’m not so sure of that. You may control the cracking and make it look “on purpose” would be to make a radial saw cut edge to pith (center) so one pie shaped crack occurs instead of multi splits

looking to bring out the natural colors (the red/orange tones not necessarily the yellow), while adding a bit of warmth and richness to some cedar planks for a ceiling project. What would you suggest?

Hello Eric! I have an Alder front door and I’m wondering what I should use to clean/protect it. I live in the scorching heat of Las Vegas if that makes a difference! A friend offered me some Teak Oil but I don’t know if it’s something I should consider. I’d love your thoughts! Thank you! Kathy

Hello, I am installing floating walnut shelves in my kitchen next to my stove. I would like to have as natural look as possible. Do I need a finish or can I leave the wood in its natural state? If I do need a finish, what would you recommend that would give the most natural look?

I have a friend refurbishing an old (90+ years) house bought out of foreclosure. He was told the floorboards are red pine and he would like to replace some of the ones in poor condition. As the boards are fairly dark and knowing wood generally darkens as it ages, I wonder whether he should stain red pine or use another wood which would look similar to red pine (and might be more affordable and/or available) so that the new boards blend in better. He’s trying to keep his costs reasonable as breaking even may be the best he can do.… Read more »

If there were only a few boards to replace, I’d look into salvage yards that may have the same old growth flooring planks reclaimed from other houses in the neighborhood.

I am trying to repair discoloration on three small areas of a mango wood table. The color description is “midtone brown”. I am using wood stain and getting closer to matching the color. However, I am at a loss about the type of finish to use once I am comfortable that the color is okay. The areas i am trying to fix have become flat and duller than the finish on the rest of the table. The table’s regular finish is not shiny. It is kind of a muted finish. Can you help me determine what kind of finish to… Read more »

It’s hard to say without knowing the exact nature of the discoloration. Very frequently, these types of spot discoloration are because the original film finish on the piece has worn through in some areas, exposing the bare wood to the elements, where it begins to oxidize and discolor. In situations like this, unfortunately, the best way to get consistency is to strip the entire layer of finish off the table, sand down to bare fresh wood for a uniform color, and then finish from there.

Hello! I’m looking to add a finish to my unfinished maple table and cannot decide on which oil to use. I would like to keep it natural, no chemicals or offensive smells because I have two small children and would like a non toxic finish. If I use a food grade oil, will it not go rancid over time? Let’s say I use linseed, walnut, or organic hemp, is there an advantage to using one or the other? My main concern is it going rancid

If this is a dining room or kitchen table a bomb-proof finish is best. I think any oil finish would be quickly defeated by Kool-Aid spills. The two dining room tables I’ve redone were finished with Miniwax Polyurethane (brush-on) and a General Finishes wiping varnish, both of which produced pleasing and durable results. Though certainly poisonous in liquid form, I’m not sure how toxic either one of these finishes is once dry. Miniwax is a common choice for finishing wooden floors, and I’ve never heard of anyone raising concerns about children playing on the floor. I think the bigger issues… Read more »

We are having a a wood carving done out of a hard maple stump. It will be kept outdoors. The carver said just put linseed oil on it once a year. After reading several articles, I’m so confused! The dark color doesn’t bother us, I’m just confused by the process…one article said add paint thinner to the linseed oil, and apply once a year. A second article said apply once a week, once a month and once a year…wha?? I just want to do this the right way. Any help is greatly appreciated.

You probably would want to use a spar urethane. Minwax Helmsman is made for the outdoors and works well.

For BLO, it is once a week for a month, once a month for a year and then once every year. If you do that, it will be well protected for a very long time.

Hi- I really appreciate your site. We are in the process of sealing the large reclaimed wormy American chestnut dining table we built. The base is quite rustic built with reclaimed beams and the top has the characteristic small holes. We were hoping for a recommendation for what type of product would be best to seal the table. We tried osmo farblos (a wax based) which sat white in the small holes and notches- so we ended up sanding that back and scrubbing w mineral oil to fix that. We are back at square one. Our ideal finish would not… Read more »

Just to clarify, did you really scrub it down with mineral oil, or do you mean mineral spirits? The first is an oil that will persist in the wood, while mineral spirits is a solvent that will eventually evaporate and leave a clean surface for finishing.

Hi –

Mineral Spirits!

Looking forward to your suggestions

Kathryn Schweier

You may use a wax filler with a dark pigment added

Hi Eric! Was wondering if you have a reference to a book or an article explaining the physics behind “weeping” of oil finishes/stains when they are over-applied? Sometimes, wood would initially soak in numerous applications of e.g. 1:1 tung oil/solvent mixture without a problem. However, after a few days, the wood would start pushing the oil back out on the surface over the period of days or weeks. Wood movement might play a role but I’m not sure it could be a major reason. Could it be due to faster soaking of the solvent inside the wood capillaries and subsequent… Read more »

Capilarity can work both ways. When you wipe oil on the surface is wetter and pores pull the oil in. As the surface “dries”, oil can flow the other way. Further, if the piece warms expanding air in the work pushes oil out.

I have a small bowl tray that we bought years ago that is made out of cucumber wood. I recently realized that the olive oil my husband used to preserve it has created a ugly dirty finish so I cleaned it down to the bare wood. What finish should I use to preserve it in future? We use it for holding any seasonal produce we are using to cook at the time.

Since it’s likely some oil remains try a wiping urethane oil/varnish in an inconspicuous spot. If the spot doesn’t harden satisfactorily, try wiping the wood with mineral spirits to remove more olive oil before the urethane

Polymerize is not a ‘fancy chemistry word for dry’… polymerize is to become plastic. The oil becomes a thin plastic film of differing degrees of hardness depending on which polymerizing oil you use. Please be aware, everyone… tung oil has been known to affect those with allergies such as asthma, eczema, and contact dermatitis, over time by accumulative sensitization. Walnut oil is, of course, dangerous to those with tree nut allergies. Linseed seems to be the most innocuous, of the ‘drying’ (polymerizing) oils. For the kitchen table mentioned above, I would make my own mix of carnauba, beeswax and linseed… Read more »

Hello. There is very little info in general about refinishing or restoring Danish Rosewood mid century furniture, I.e dining table in my case……on the internet. Even youtube isn’t helpful. Can you please suggest how to tackle such a wood table, which by the way has sun damage? I hate to sound dumb, but what kind of stain would I use on rosewood.? It looks like shellac is good finish for rosewood reading what little info was available on a couple of websites. Am I wrong? Please help. Thanks in advance for any help.

Mid century and later Danish is usually finished with sprayed lacquer and repairs are best left to professionals. Shellac is easier to repair. To test for shellac dampen a hidden spot with pure alcohol; shellac will become sticky to the touch and dry hard again.

Would raw linseed oil work on Mopani and very old Teak. I am in the process of making a few lamps out of these woods. And also need to polish up Wild Bush Olive. I also want to sand down and finish off an 1820 dinning room table top. It has been stained over the years with water, so its a project of mine. What would be the best to oil and finish this off with? This table came up to Africa with the 1820 pioneer’s. Very old family piece. The table in places has very deep grain that I… Read more »

I wouldn’t use raw linseed oil because it doesn’t really ever harden. In terms of oils, I’ve found a polymerized (not raw) tung oil seems best.

I have been given a large outdoor ten place teak dining set. It has gone a little pale and has mildew spots on the tale and ten chairs. As we live in Spain and it will be outside all the time what’s the best wa6 t9 treat it and protect it?

I need some advice. I have a home crafted table that is my kitchen table it gets lots of daily use and I can’t seem to have any luck with polyurethanes (both oil or water) they peel after a month of use. Like I said this table gets lots of daily use. What do you recommend for me to use to protect it. Also what type of wood is this? Is it pecan or oak?

I would recommend using a paste wax (oil and wax mixture) to finish this. I have an oak table that I use every day that I finished using my homemade food safe oil/wax paste. This gives the wood a nice warm colour and maintains it’s water repellance and reduces wear on the surface. If you would like the recipe for my wood wax I am happy to tell you.

Difficult to identify the wood from this image, would be easier if it was cleaned and finely sanded.

I am interested in your wood wax recipe.

Thank You

John Harrison

Thank you for your interest, the recipe I use is never exact and changes depending on the wood I am working with but is roughly as follows:

-1/4 beeswax

-1/8 carnauba wax

-5/8 oil (mixture of coconut, olive, unboiled linseed, walnut, mineral oil (adjust to the wood’s preference.))

-chips of pine resin (be sure to filter out residue)

The finish is designed to condition the wood and leave a natural feeling non-slippery surface that is water repellant. I use it on table tops, furniture and tool handles.

In my experience polyurethane peeling after a month suggests that there is something already on and in the wood, like lipids(plant or animal, including from human sweat) or wax or a non-drying oil, which left the polyurethane nothing that it could stick to. I’ve seen dark looking pores like that be from a wood stain applied as part of the original finishing or a previous refinishing, and/or “dirt” collected into that residual oil or wax or lipids. One test I would do is rub on a bit of saliva, which might start to loosen lipids. Then some gentle scrubbing with… Read more »

If you do use a varnish, whether urethane or other, lightly sand (180+ grit) after each thoroughly dried coat except the final, and remove the residue. This will leave a smoother final coat. Each sanding from the second coating on can be lighter than the previous sanding.

If neither oil or water based finish sticks you may have a non polymerizing oil finish. If the finish is not glossy at all try a solvent (thinner) on a hidden spot to wipe the wood clean, sand lightly and try your preferred finish.

First off, I get that this is an old thread. I would still like to throw in my two cents simply for the people who still read thru these posts with the intent of gaining useful knowledge from people who have “been there, done that” (professionals) and to get ideas from people who have been or are currently in similar situations. With no disrespect to any of the above replies, I would like to offer a solution. The OP stated that she needed something durable as the table is in heavy use and gets all sorts of traffic… daily. She… Read more »

Have a cherry cupboard dated between 1734-1826, what oil should I us. Told not to use linseed.

Walnut oil or tung oil are good choices, I don’t see why you shouldn’t be able to use raw linseed though.

I would be very reluctant to permanently change the patina of this historic piece with any oil or varnish. a damp cloth with mild soap to remove the worst grunge and a thin coat of high quality paste wax will restore and protect while preserving its well earned history. Oiling or refinishing will destroy any historic or collectable value. please think twice and seek the advice of an expert.

What oil is good for western red cedar to keep that rich look

You could talk about catalized and pre cat laqures. these are harder and resist moisture, used in commercial cabinetry. The nut woods bleach out with UV light so I stain them (oil Stain) in their naturial colors before spraying on pre-cat laqure

I found linseed oil the best finish for white oak exterior work, easy to roll or brush on a new coat yearly or as needed

I have a new kitchen table made of rubber wood and acacia. I want to give it extra protection from food and liquids. What do you recommend? Thanks.

I make pens and have been using ca as a finish but I find that no matter how I sand down the ends I get cracks is there a strong durable finish for Padauk and cocobolo that you can recommend

What do you mean you get cracks? Do the cracks develop when you press the fittings into the brass tube?

Try to avoid overheating the finish when cutting back and polishing on the lathe as this can cause tiny cracks to develop which can create faults on the final product.

Elsewhere on your web site I read about the safety benefits of using a dust collector. I have a Makita belt sander with a 1 1/8 inch dust port to the rear of the tool. I have tried many sources, unsuccessfully, to find a dust collector made by Makita. One source, in the U.K., won’t sell products internationally. Could you give me a recommendation, for any brand, and a supplier to contact? I need the on/off capability when the sander is turned on/off, and a hose on the tool end that has a 1 1/8 inch diameter opening. Thank you.

I’ve used a product called iSocket to turn a regular shopvac into a power-activated tool vacuum. https://amzn.to/2QaAqvk

Also, if you can’t quite find the exact size, I know there’s sort of stepped cone-shaped adapters that you can buy to adapt to a variety of hose and port sizes. If all that fails, I’ve actually wound tape over and over around the dust port (before attaching it to anything) to bring the actual port up to a standard sized diameter.

Still scratching my head on what is best to use to protect acacia. I have a coffee table to I want make sure doesn’t absorb coffee etc from some accidental spill. Is that a wax or an oil

The best protection from staining from liquids will be found in a film building finish, which would technically be neither a wax nor an oil. Something like polyurethane or lacquer.

By sealing the wood with a layer of shellac then applying a wax/oil paste the surface can be made water repellant.

Should I use any type of furniture oil like orange oil on cherry cabinet doors that have 3 coats of wipe on poly? I was told to do that with a custom cherry hutch once upon a time, but I don’t know what the finish was on that piece. Thanks for the great information on this site too!!

Great resource of information. My question is, I am doing a commission table lamp using Black Walnut, my customer loves it, but commented that she is worried it will get too dark when I finish it. I know that when I use Polyurethane it will darken the Black Walnut. What would be a better option that won’t darken it as much.

thanks.