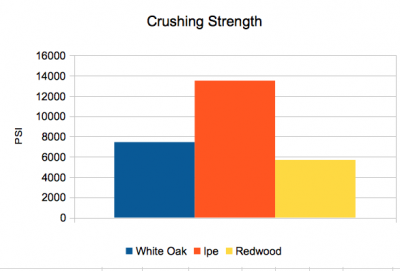

Sometimes known as compression strength parallel to the grain, this is a measurement of the wood’s maximum crushing strength when weight is applied to the ends of the wood (compression is parallel to the grain).

This number is a good indicator of the wood’s strength in applications such as deck posts, chair legs, or other circumstances where the load being applied is parallel rather than perpendicular to the grain.

In practical terms, the number itself isn’t all that meaningful, but it becomes useful to use in comparison with other woods. For instance, Ipe is known to have excellent strength properties among imported species, and has a crushing strength of 13,510 lbf/in2 (93.1 MPa). In comparison, White Oak is a well-known wood used in cabinetry and furniture, and has a crushing strength of 7,440 lbf/in2 (51.3 MPa), and Redwood is commonly used for decking, and has a crushing strength of 5,690 lbf/in2 (39.2 MPa).

Get the hard copy

So much for Egyptians using wooden sleighs to move stone. The weight of the Unfinished Obelisk is over 20 million pounds. Wood vaporizes underneath such forces and moments.

I was looking for other issues that led my to the crushing/compression strength(parallel) but landing here did get me the link to :Mechanical Properties of Wood

David E. Kretschmann, Research General Engineer

I have a lot to research for what I want to find out which is requirement on many fronts. I know you are busy person but I’d like to run an idea by if you have the time on the combination of aspects/specifications I’d like to find in a wood to make a staff type combat weapon.

Where can I find numbers for wood strength in tension parallel to the grain? Crushing strength is about compression, and elasticity is about bending perpendicular to the grain, so not really what I want either. I’m building a guitar and want to make a top from Sitka Spruce and another top from carbon fiber sheet, and compare them. I know Sitka Spruce tops on guitars are typicaly 1/8″ (3.2mm) with additional bracing. Elastic (flexure) modulus of Sitka Spruce is 11 GPa. But you don’t list the tensile strength of Sitka Spruce. I need to figure out an equivalent thickness for… Read more »

Can’t address all your questions, but the USDA wood handbook has more in-depth information on select species of woods, sitka spruce being one of them. https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr190/chapter_05.pdf

Hello Eric, I would like to delve further into this, as per Gregory’s enquiry ut for entirely different reason…. I have started making laminated longbows and looking into what woods are best suited. I have read your piece on this subject and fascinated by the “Bow Index” you produce relating MoR with MoE. However, as pertinent as this is it is not the whole story. The inner laminate, facing the archer (belly), is subject to compression. The centre laminate (spine) merely flexes but the outer laminate (back) is under tension. Woods ideally suited to spine include Purpleheart from S. America… Read more »

You’re right about the USDA links, they recently changed their link structure so I’ve had to update all the links, but overlooked links in the comments. It should be updated to work now.

Be aware that the speed of sound along and perpendicular to the grain both affect the performance of a guitar top. So strength is only a small part of the story.

Fot example, this is the reason that the grain of the wood runs along the long dimension of the guitar.