|

Common Name(s): Sweetgum, Redgum, Sapgum, satin walnut Scientific Name: Liquidambar styraciflua Distribution: Southeastern United States Tree Size: 65-100 ft (20-30 m) tall, 2-3 ft (.6-1 m) trunk diameter Average Dried Weight: 34 lbs/ft3 (545 kg/m3) Specific Gravity (Basic, 12% MC): .46, .55 Janka Hardness: 850 lbf (3,780 N) Modulus of Rupture: 12,500 lbf/in2 (86.2 MPa) Elastic Modulus: 1,640,000 lbf/in2 (11.31 GPa) Crushing Strength: 6,320 lbf/in2 (43.6 MPa) Shrinkage: Radial: 5.3%, Tangential: 10.2%, Volumetric: 15.8%, T/R Ratio: 1.9 |

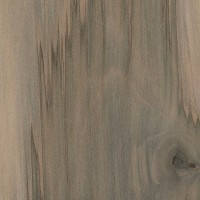

Color/Appearance: Wide sapwood is whitish to light pink or tan color, and is sometimes referred to as “sapgum” or “sweetgum.” Heartwood is gray to reddish brown, and is commonly referred to as “redgum.” Heartwood with darker black streaks is called “figured redgum.” Quartersawn pieces have a ribbon-stripe appearance.

Grain/Texture: Grain is interlocked, with a very fine, uniform texture. Good natural luster, this wood has sometimes been called “satin walnut.”

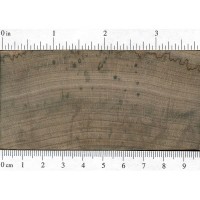

Endgrain: Diffuse-porous; small pores in no specific arrangement, very numerous; exclusively solitary and/or in radial multiples of 2-3; tyloses common; growth rings indistinct; rays not visible without lens; parenchyma not visible with hand lens.

Rot Resistance: Heartwood sections are rated as moderately durable to non-durable regarding decay resistance, while the sapwood is perishable. Also susceptible to insect attack.

Workability: Generally easy to work, though planing can produce tearout due to interlocked grain. Sweetgum is known to warp and distort badly during initial drying. (After initial drying, distortion is significantly less, but the wood still experiences an appreciable amount of movement in service.) Turns, glues, stains, and finishes well. Responds moderately well to steam bending.

Odor: No characteristic odor.

Allergies/Toxicity: Although severe reactions are quite uncommon, Sweetgum has been reported to cause skin irritation. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Because the sapwood is so wide, only older mature trees will yield the darker Redgum heartwood lumber. Sapgum is widely available at low cost, while Redgum is more uncommon, and prices can be in the mid range for a domestic hardwood, with prices for figured and/or quartersawn pieces costing more.

Sustainability: This wood species is not listed in the CITES Appendices, and is reported by the IUCN as being a species of least concern.

Common Uses: Veneer, plywood, furniture (speaker/acoustic cabinets), interior trim, boxes/crates, and turned objects.

Comments: Not to be confused with various Australian species in the Eucalyptus genus that are also referred to as “red gum.”

None available.

None available.

Scans/Pictures: A special thanks to Mike Leigher for providing the wood sample of this wood species.

I had a large sweet gum that had been blown down milled while milling all of the other lumber for my 100 yr old barn restoration. Surprisingly it was some of the most beautiful wood I have ever seen.

I attached some photos. I assume this would be what the site is calling figured red gum.

I had it cut for making beams so that’s what I used it for. If anyone does mill some, enjoy the smell lol.

I have 3 massive and i mean massive gums that are at least 5 feet in diameter. I am going to be cutting them down and am wondering if it is worth it to get the mill out here to cut me up some slabs. I guess im wondering if age would play a role with figure as i would only want it if it was highly figured.

Our wall (internal) have lasted 64 years, show no signs of wear, and are constantly commented about by people. Worth the effort if you enjoy wood.

Will this work as flooring or interior walls? The 36” diameter wood from the sweet gum?

Hi,

I am thinking about turning some salad bowls from a sweetgum tree that my neighbor took down. Is this wood hard enough for salad bowls?

Thanks,

Rob

I just turned a small bowl today. It looks really nice but the wood is very soft and light.

I’m having several sweet gum logs milled soon and was thinking of having them milled into 2x and 4x lumber. My plan was to use them to build a carport type shelter for my ATV, lawn mowers, wagons, etc. The logs are 16′ long and big enough to give me 4×4, 4×8, 2×10, etc.

Can this wood be used for this application? If so any special considerations?

Sweet Gum is in the database for construction, you will need to have it graded and stamped. Strength is a little under yellow pine. The wood needs to be weighted or clamped to keep it from warping while it dries. Has poor rot resistance though pressure treated it is popular for railroad ties.

Hello I’m trying to decide on wood for endgrain wood flooring and sweet gum is plentiful on my property and I personally think it is beautiful wood. So I’m looking for some opinions on this…will even be a suitable option. My plan is to have 6”x 6”x 3/4” tiles for the entire house.

No. It requires special handling and drying (12/4 or 16/4 sawn and air dried on stickers 2-3 years before kiln drying – during which it must be weighted down) – It tends to twist and works for furniture only if used properly. It would almost certainly warp and twist every which way if 4/4 planesawn and then dried, planed, jointed. Tongue and groove only helps to a point. Not only that, it really isn’t hard enough. Go for white oak, pecan/hickory, maple, ash – avoid cherry, gum, sycamore (same problems as gum but also a bear to seal), pine, cedar… Read more »

She said, “endgrain flooring”, and specified 6″x6″ tiles. Presumably you would cut the log into 3/4″ cookies, cut as many 6×6 tiles out of the cookies, and then lay the tiles out to dry for a year. End grain should not warp too much, but it may crack. Another consideration is the endgrain orientation will expand and contract in both directions as opposed to a traditional side grain orientation which will mostly only expand and contract across the width of the boards. I don’t know if the end grain of the gum is quite as attractive as the side grain.

I turned some small decorative bats out of some spalted sweetgum I have. They’re gorgeous, but this wood Is not hard enough for a functional bat.

Have you ever heard of using sweetgum to make a baseball bat?

I don’t think it’s hard enough for a bat