|

Common Name(s): Rubberwood, plantation hardwood, parawood, Malaysian oak Scientific Name: Hevea brasiliensis Distribution: Native to Brazil, but extensively cultivated in tropical regions, especially in Asia Tree Size: 75-100 ft (23-30 m) tall, 1-3 ft (.3-1 m) trunk diameter Average Dried Weight: 37 lbs/ft3 (595 kg/m3) Specific Gravity (Basic, 12% MC): .49, .59 Janka Hardness: 960 lbf (4,280 N) Modulus of Rupture: 10,420 lbf/in2 (71.9 MPa) Elastic Modulus: 1,314,000lbf/in2 (9.07 GPa) Crushing Strength: 6,110 lbf/in2 (42.1 MPa) Shrinkage: Radial: 2.3%, Tangential: 5.1%, Volumetric: 7.5%, T/R Ratio: 2.2 |

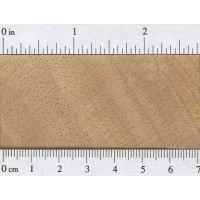

Color/Appearance: Heartwood naturally a light blonde to medium tan color, sometimes with medium brown streaks. Sapwood not distinct from heartwood. Color tends to darken slightly with age. Frequently colored or stained when used in furniture construction.

Grain/Texture: Grain is straight, with a somewhat coarse, open texture. Low natural luster.

Endgrain: Diffuse-porous; large to very large pores in no specific arrangement, very few; solitary and radial multiples and rows of 2-4; tyloses and heartwood mineral/gum deposits (brown) occasionally present; growth rings usually indistinct; narrow to medium rays barely visible without lens, normal spacing; parenchyma diffuse-in-aggregates and banded (reticulate).

Rot Resistance: Rubberwood is perishable, and has very little natural resistance to decay. It is also susceptible to fungal staining and insect attacks.

Workability: Easy to work with both hand and machine tools. Rubberwood tends to warp and twist in drying, though it is fairly stable in service once seasoned. Glues, stains, and finishes well.

Odor: Rubberwood has an unpleasant sour odor while being worked, especially when green, which subsides upon drying.

Allergies/Toxicity: Besides the standard health risks associated with any type of wood dust, no further health reactions have been associated with rubberwood in particular. However, individuals with natural latex or rubber allergies may have reactions to rubberwood. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Rubberwood is rarely exported in raw lumber form, but is instead worked into a variety of furniture, kitchen, and other household items and then exported and sold elsewhere.

Sustainability: This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species. Rubberwood lumber is typically taken from rubber plantations where the trees are tapped for latex, and harvested at the end of their useful life cycle—typically after about thirty years.

Common Uses: Furniture, cabinetry, interior millwork, kitchen woodenware (cutting boards, knife blocks, etc.), and other small, specialty wood items.

Comments: Despite its common name, rubberwood isn’t any more elastic or soft than comparable hardwoods of similar density/weight—the name is derived from its use on rubber plantations, where the sap is harvested as a natural source of latex. Rubberwood is seen on a wide variety of (mostly inexpensive) Asian imported furniture. Many big-box and home furnishings retailers have pieces made of rubberwood. When sold in this capacity, the wood is sometimes marketed under ambiguous monikers such as plantation hardwood, or worse, Malaysian oak, though it is not related to true oak in the Quercus genus. The wood is commonly stained and available in a wide range of colors and finishes.

None available.

None available.

How durable is Vietnam Rubberwood when it is the platform for filmfaced plywood?

Can you compare it whit Chinese Eucalyptus filmfaced plywood?

I wonder is there any difference between Vietnam Rubber wood and Malaysian Rubber wood

I’m think of using it as a Vanity top in the bathroom, where their will be a shower also.

How well will the timber do in this scenario?

Don’t do it! It is highly susceptible to rot.

What if I seal it with a stain or eurothaine?

In Australia, it is generally sold as Hevea and is used in gluelam panels

I’d like to begin a project of refinishing a Parawood table that has been stained darkness I prefer the light natural tones of the wood. Then, is it possible to properly refinish by stripping, sanding, etc., and apply the proper applications to maintain the light nature of the wood while also warding off rot with the correct chemicals? If so, where can I find more information to do this project? Thanks.

Rot resistance via chemicals really isn’t possible with home treatment, and involves treating the wood in a high-pressure preservative. Best you could do is apply a film-building finish like a spar or poly urethane. Most of these exterior products are oil-based, so there’d be at least some yellowing that would come from the oil itself, but nothing too drastic. These film finishes would have to be re-applied on maybe a semi-annual basis in order keep the protection going, but a lot would depend on how many coats were initially applied and how thick the finish is.

Anyone know how well the vinegar and steelwool stain works on the Parawood?

All the percussion industry worldwide use hevea brasiliensis wood for congas, bongos and batás factoring. Amazing sound and great visual effect.

Is rubberwood suitable for kitchen cabinetry; in particular – two (2) lower cabinet columns on either side of the sink?

Does this wood make good beds?

I don’t see why not. It’s used in furniture all the time.

Would you recommend using it as a cutting board?Is it safe?

I wouldn’t use rubberwood as a cutting board since there’s a risk of sensitization to latex, which can lead to a lifelong allergy to NRL. According to the CDC 6% of the population is allergic to latex, 17% of healthcare workers and 33% of children who had surgery. It is better to stay away from latex and rubberwood if possible.

Thats exceedingly unlikely. The current thought about latex allergy is due to the processing of the latex to use for gloves etc. Interestingly there is essentially 0 reported cases of allergies to all latex mattresses!

As a member of the largest Latex Allergy support group (6k members) I see dozens of new patients every week developing an allergy to latex because of repeated exposure via gloves, mattresses, balloons, catheters and orthodontic rubberbands. As allergists continue to warn us about the dangers of sleeping on a latex mattress they also recommend avoiding food contact with utensils or cutting boards made of rubberwood. Just ask a healthcare professional and you’ll see how prevalent this allergy is, even if it doesn’t make the headlines in the press. Unfortunately there is a real lack of awareness and education about… Read more »

is this a hard of softer wood

is it stain resistance

hardwood, stain resistance can be done via a clear a sealer/clear coat.

Is it machined into into flooring and is so can it be refinished?

What is the acoustic properties of rubberwood?can you share it?

Sorry, not poplar. Poplar’s super soft!

It says right at the top of the page—that’s the whole point of this website! It’s hardness is 960 lbf, which puts it on par with walnut, cherry poplar. A softer hardwood.

heartwood is can be quite hard nanabana – but its also kinda “bendy” and rubbery, but it comes from the latex tree so it figures. maybe similar to walnut in hardness, but the woods are much different in characteristics