|

Common Name(s): Pitch Pine Scientific Name: Pinus rigida Distribution: Northeastern United States Tree Size: 50-65 ft (15-20 m) tall, 2 ft (.6 m) trunk diameter Average Dried Weight: 34 lbs/ft3 (545 kg/m3) Specific Gravity (Basic, 12% MC): .47, .55 Janka Hardness: 620 lbf (2,760 N) Modulus of Rupture: 10,800 lbf/in2 (74.5 MPa) Elastic Modulus: 1,430,000 lbf/in2 (9.86 GPa) Crushing Strength: 5,940 lbf/in2 (41.0 MPa) Shrinkage: Radial: 4.0%, Tangential: 7.1%, Volumetric: 10.9%, T/R Ratio: 1.8 |

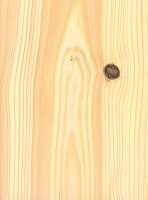

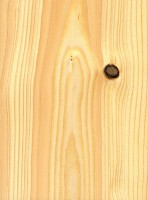

Color/Appearance: Heartwood is reddish brown, sapwood is yellowish white.

Grain/Texture: Straight grained with a medium texture.

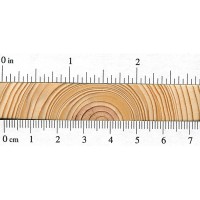

Endgrain: Large resin canals, numerous and evenly distributed, mostly solitary; earlywood to latewood transition abrupt, color contrast relatively high; tracheid diameter medium-large.

Rot Resistance: The heartwood is rated as moderate to low in decay resistance.

Workability: Overall, Pitch Pine works fairly well with most tools, though the resin can gum up tools and clog sandpaper. Pitch Pine glues and finishes well.

Odor: Has a distinct smell that is shared among most species in the Pinus genus.

Allergies/Toxicity: Working with pine has been reported to cause allergic skin reactions and/or asthma-like symptoms in some people. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Pitch Pine is sold and mixed interchangeably with other species as Southern Yellow Pine, which is widely available as a construction lumber for a modest price.

Sustainability: This wood species is not listed in the CITES Appendices, and is reported by the IUCN as being a species of least concern.

Common Uses: Southern Yellow Pine is used for heavy construction, such as: bridges, beams, poles, railroad ties, etc. It’s also used for making plywood, wood pulp, and veneers.

Comments: Although much more predominant in northern states, Pitch Pine is technically considered to be in the group of Southern Yellow Pines, (though it is a very minor species), and is found as far south as northern Georgia.

- Austrian Pine (Pinus nigra)

- Caribbean Pine (Pinus caribaea)

- Eastern White Pine (Pinus strobus)

- Jack Pine (Pinus banksiana)

- Jeffrey Pine (Pinus jeffreyi)

- Khasi Pine (Pinus kesiya)

- Limber Pine (Pinus flexilis)

- Loblolly Pine (Pinus taeda)

- Lodgepole Pine (Pinus contorta)

- Longleaf Pine (Pinus palustris)

- Maritime Pine (Pinus pinaster)

- Ocote Pine (Pinus oocarpa)

- Patula Pine (Pinus patula)

- Pinyon Pine (Pinus edulis)

- Pond Pine (Pinus serotina)

- Ponderosa Pine (Pinus ponderosa)

- Radiata Pine (Pinus radiata)

- Red Pine (Pinus resinosa)

- Sand Pine (Pinus clausa)

- Scots Pine (Pinus sylvestris)

- Shortleaf Pine (Pinus echinata)

- Slash Pine (Pinus elliottii)

- Spruce Pine (Pinus glabra)

- Sugar Pine (Pinus lambertiana)

- Sumatran Pine (Pinus merkusii)

- Table Mountain Pine (Pinus pungens)

- Western White Pine (Pinus monticola)

- Virginia Pine (Pinus virginiana)

Hi – I own and keenly race in a fleet of traditional 100 year-old wooden sailboats around 27ft long, carvel construction with hulls formed from pitch pine planks on oak transverse frames. We have a constant debate over the use of traditional versus modern materials. A quote from another owner recently reads as follows, “…..before buying [boat name] I spent a lot of time talking to shipwrights and asking certain questions, one of which was why modern glues were not used. The answer was because the original Sunbeams were built using pitch pine planking which is so resinous that epoxy… Read more »

I’ve certainly never had a problem using West or SP epoxies with Pitch Pine – we built a Saga 40 nearly 40 years ago where the owner specified Pitch Pine deck beams. She’s still sailing today as far as I know.

Great info on specs for those who learn about wood like us. Moreover, I have official sources from wood-database