|

Common Name(s): Leopardwood Scientific Name: Roupala montana (syn. R. brasiliense) Distribution: Central and South America Tree Size: 100-130 ft (30-40 m) tall, 2-3 ft (.6-1.0 m) trunk diameter Average Dried Weight: 55 lbs/ft3 (885 kg/m3) Specific Gravity (Basic, 12% MC): .73, .89 Janka Hardness: 2,150 lbf (9,560 N) Modulus of Rupture: No data available Elastic Modulus: 2,887,000 lbf/in2 (19.91 GPa) Crushing Strength: 7,280 lbf/in2 (50.2 MPa) Shrinkage: Radial: 3.5%, Tangential: 8.8%, Volumetric: 11.5%, T/R Ratio: 2.5 |

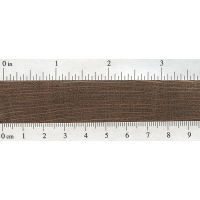

Color/Appearance: Has a very conspicuous flecking that gives this wood its namesake. The wood itself is a medium to dark reddish brown with grey or light brown rays, which resemble the spots of a leopard. Like other woods that exhibit the strongest figure in quartersawn pieces, (such as Sycamore), Leopardwood has the most pronounced figure and displays the largest flecks when perfectly quartersawn; this is due to the wood’s wide medullary rays, whose layout can be seen the clearest when looking at the endgrain.

Grain/Texture: Has a fairly coarse texture and straight grain.

Endgrain: Diffuse-porous; small to medium pores in tangential rows; solitary and tangential multiples of 2-3; deposits in heartwood occasionally present; growth rings indistinct; very wide rays easily visible without lens; parenchyma banded, diffuse-in-aggregates.

Rot Resistance: Most species are reported to be very durable regarding decay resistance.

Workability: Fairly difficult to work because of its high density and tendency to tearout during planing. Leopardwood glues and finishes well.

Odor: No characteristic odor.

Allergies/Toxicity: Although there have been no adverse health effects reported for Lacewood in the Roupala genus, several other genera in the Proteaceae family have been reported to cause eye and skin irritation. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Prices for Leopardwood tend to be medium to high for an imported wood.

Sustainability: This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species.

Common Uses: Veneer, cabinetry, fine furniture, musical instruments (guitars), and turned objects.

Comments: Leopardwood is frequently confused with Lacewood, and is sometimes referred to as such. In its vaguest sense, the term “lacewood” is used to describe any wood that displays figuring that resembles lace, (which would technically include Leopardwood). Attempts to identify a specific board macroscopically may be difficult. Two Australian species, Northern Silky Oak (Cardwellia sublimis), and Southern Silky Oak (Grevillea robusta) can both look very similar, and are sometimes sold as Australian Lacewood.

Leopardwood (Roupala spp.) can usually be separated from most species of Lacewood (Panopsis spp.) based upon its darker color and higher density. Additionally, when comparing the endgrain of these two genera, Leopardwood has wider spaced parenchyma bands: approximately 3-4 per mm versus 5-6 per mm with Lacewood.

Proteaceae family:

Scans/Pictures: Note the pair of pictures demonstrating the use of a bandsaw in resawing a small piece of Leopardwood to fully display the ray flecks in the wood.

Custom stainless Damascus damasteel knives I’ve just had commissioned finished with Leopard wood.

Stunning finish to them.

Was gifted some of this wood and want to use it for project but I’m getting terrible tearout on the planer. Any advice?

Hand plane it with an incredibly sharp blade. I mean RAZOR sharp.

After 49 years of knifemaking I finally got around to using leopardwood on my fillet blades! I was very impressed with the workability of the wood and the final polish finish. Doing a palm swell styled handle, really makes this grain pop!

I’ll definitely be using this wood again!!

How does this wood bend?

My recent experience was not very successful. I was using pieces ~1/4″ (6mm) thick and 1/2″ (12mm) wide approximately 1 foot long for pipe stems. Steamed for ~15 minutes (which is great for Oak or Walnut). Wood seemed sufficiently hot and damp, but the waxy nature of the piece I was using may have been deceiving. After bending in my form which only deflects the wood about 2″ over the foot, it lost about half the bend when it was removed from the form about 24 hours later. Using Titebond glue was also not very successful. Glue didn’t seem to… Read more »

Example of snack spoon made with Leopardwood.

So, leopardwood is not toxic?

My 25 year old son was killed in car crash earlier this year and so I just finished an intarsia project as a Christmas present for his girlfriend. She loved sunflowers and my son grew them for her and they called each other two-peas-in-a-pod. I used leopard wood for the center of the sunflower.

Terribly sorry for your loss. Wonderful idea.

Sorry for your loss. You do beautiful work!

So sorry for your loss. The work you did is special and awesome.

Here’s something I recently made from Leopardwood. It’s a single piece, with the center cutout and filled with polyurethane resin, then sculpted afterwards.

A little confused…. “Leopardwood has wider spaced parenchyma bands: approximately 3-4 per mm versus 5-6 per mm with Lacewood.” 3-4mm doesn’t seem to be wider than 5-6mm.

You have to keep in mind that the number is “per mm”. For reference on a road or walking path, if I said that there are 4 distance markers per mile, that would mean that the markers on the path were spaced wider than if I said that there were 6 distance markers per mile. Think of the parenchyma bands as “distance markers” — but on a much smaller (mm) scale. Hopefully that makes sense.

Hello, I recently tried to turn a bowl out of Leopardwood. At first the results were beautiful. I left to go to the store and when I returned the bowl, which was only about 60% complete, had cracks all around the outside but not on the inside. I don’t know why this happened. Any ideas?

It was most likely partially seasoned, as a general rule of thumb always leave your timber to acclimatise to your workshop for at least a month. Then you will see if it is seasoned or not

I love to turn green wood- I collect and bag the shavings in an air tight ziploc, and turn for ten minutes at a time – then surround the bowl with the shavings using a plastic bag, let it sit for 10 minutes while I sharpen tools (or clean the shop !) When the bowl is done, it goes in the ziploc (after being weighed) and I take it out of the bag for ten minutes each day, and when the weight stops changing it’s done. Try turning green apple –

what a joy !!!!!

Hey Eric, I’m a small shop knife maker and stumbled across your website a couple years back and have been referring to it since. I just saw the posters and bought two, one for myself and one for my mentor. And just now came across the link and what led me to the page titled, ‘The Most Valuable Wood in the History of Mankind.” Nice!

Great site. Good man.

How stable is South American Leopard Wood? It has a T/R ratio of 2.5 which seems vey high! How stable will or would it be musical instruments? Would it cause shrinking or expansion problems, which would or could lead to cracks & or warpage in Guitars & Dobros ?

bowl empty pockets

I’m doing my first Stave Drum Shell with it & it is a strange but wonderful species! Very unique texture & has a really cool 3D appearance, will definitely be using it again!

Did you ever get to build this? If so how did it turn out? Any pics?

Is Leopardwood good for counter top?

I’d never worked Leopard Wood (isn’t there an army fort with that name??) before. I sanded my project to 320, then used 400 grit wet/dry paper to hand sand it using velvit oil, a penetrating oil made here in Wisconsin that polymerizes upon drying. I didn’t expect the allergic reaction that followed. My eyelids, nose and lips swelled up and my forearms turned red and they all itched like mad. Having had a full body reaction to Wisconsin cherry in the past, I started taking all my meds and got some vizine with an antihistamine at the pharmacy for my… Read more »

I had a really bad reaction to this as well. I itched everywhere for a week!