|

Common Name(s): Imbuia, Imbuya, Embuya, and variant spellings; Brazilian Walnut Scientific Name: Ocotea porosa (syn. Phoebe porosa) Distribution: Southern Brazil Tree Size: 100-130 ft (30-40 m) tall, 5-6 ft (1.5-1.8 m) trunk diameter Average Dried Weight: 41 lbs/ft3 (660 kg/m3) Specific Gravity (Basic, 12% MC): .53, .66 Janka Hardness: 970 lbf (4,300 N) Modulus of Rupture: 12,290 lbf/in2 (84.8 MPa) Elastic Modulus: 1,394,000 lbf/in2 (9.61 GPa) Crushing Strength: 6,780 lbf/in2 (46.8 MPa) Shrinkage: Radial: 3.0%, Tangential: 6.4%, Volumetric: 9.5%, T/R Ratio: 2.1 |

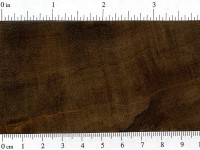

Color/Appearance: Heartwood color can vary substantially; typically medium to dark brown, sometimes with a reddish, golden, or olive-colored cast. Light grayish yellow sapwood is usually differentiated from the heartwood. Burls and wildly figured boards are commonly seen.

Grain/Texture: Grain is straight, though many boards can exhibit wild or burl-like patterning. Medium to fine uniform texture with good natural luster.

Endgrain: Diffuse-porous; solitary and radial multiples; large pores in no specific arrangement, moderately numerous; tyloses common; parenchyma vasicentric; narrow rays, spacing normal.

Rot Resistance: Rated as durable; also moderately resistant to insect attacks. Good weathering characteristics.

Workability: Produces good results with both hand and machine tools. However, pieces with wild or irregular grain may present challenges in surfacing and other machining operations. Turns, glues, and finishes well.

Odor: Imbuia has a characteristic spicy scent when being worked.

Allergies/Toxicity: Although severe reactions are quite uncommon, Imbuia has been reported to cause nose, throat, and skin irritation. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Usually available as lumber in good sizes, as well as turning or instrument blanks. Plain, unfigured lumber should be moderately priced for an imported hardwood, though figured pieces may be considerably more expensive.

Sustainability: This wood species is not listed in the CITES Appendices, but is on the IUCN Red List. It is listed as vulnerable due to a population reduction of over 20% in the past three generations, caused by a decline in its natural range, and exploitation.

Common Uses: Furniture, cabinetry, flooring, veneer, boatbuilding, gunstocks, and turned objects.

Comments: Sometimes called “Brazilian Walnut,” Imbuia bears little botanical relation to true walnuts in the Juglans genus. However, even though Imbuia isn’t a true walnut, it still possesses deep, rich colors and interesting grain patterns that rival the classic cabinet hardwood.

None available.

Scans/Pictures: A special thanks to Steve Earis for providing the turned photo of this wood species.

It was imported to South Africa as a replacement for stinkwood when the felling of the South African stinkwood was banned. It smells a hell of a lot better than stinkwood but is not as strong.Stinkwood being remarkable tough.

EB.

As others have said, the wood was imported to South Africa from Brasil paricularly in the 1950s fro furniture.

Both my father and grandfather used it to make hi fi cabinets and loudspeaker enclosures where it was favoured for its colour, denisty and even grain.

I still have two planks that were left over from their projects. One is stamped ‘KM Brasil’.

I believe imbuia is found in Southern Africa as well… at least, I bought a table in Cape Town ZA about 40 years ago… so gorgeous.

Yes It is. My Mom was from Durban, and I have my Moms Imbuia Kist (she will have called it) she must have received in gosh around 1950 . She passed away last year and I’m so sorry I didn’t get more details. It left Durban with me 17 years ago and was In New Zealand until 6 months ago where it now safely lives in Brisbane. I was looking for advice on how to restore it and came across this article.

Where are you now Juudy

Imbuia imported from Brazil was a popular furniture timber in South Africa from the 1950s to 1980s. I have several inherited items as well as a turned bowl and a telephone table I made as school woodwork projects in 1972. Currently making imbuia picture frames from my grandfather’s huge speaker cabinet!

A beautiful example; Peavey Grind 4-string

I have a guitar made of this wood on the side and back of the guitar (Taylor 414ce Ltd 2007). It is very strong n no problem in SE-Asian climate. A very unique guitar for keep

Huge fan of the site and your work! I make furniture and things out of pallets and came across an incredibly heavy, dark 1×4 that a pallet had been repaired with. It is significantly denser than any wood I’ve come across and the oils in it started to turn my brush and finish slightly brown. It is quite figured with a lot of swirls, with colors ranging from a pale olive gray with a hint of yellow to a rich brown chocolate color, hence why I’m on this page. Does anyone have any thoughts?

Being born in Brazil, this is one of the woods I remember hearing a lot about growing up when discussing furniture… Would love to find a something in the USA to work with.

I made one piece of furniture from this 30 years ago but didn’t really like the irregularity of the grain. I now have a few offcuts which I just cut from time to time just to smell it! the aroma of this wood is the most beautiful of any I’ve ever worked with.

Thinking about making a native American flute with this wood (imbuia) but have concerns

about health issues. Any input ?

I’ve already seen some bird call whistles made of Imbuia wood in Brazil. By the way, luthiers in Brazil used to make flutes with this wood, but now is illegal to cut this wood.

Margie,

This is a common misconception among some: that a wood is “thirsty” and somehow needs to be “fed” from time to time.

Wood reaches an equilibrium with the surrounding air in terms of the level of moisture that’s contained in the wood, and it doesn’t subsequently over dry or “dry out” at any point.

If the actual finish on the wood (not the wood itself) is scratched or deteriorated, it might be necessary to reapply or refinish the wood, but that isn’t needed all that often.

I have many pieces of imbuia furniture in my home. I love this wood and have had it all sanded down to it’s original. I am currently giving it plenty of oil (woodoc) and would like to know if I’m doing the right thing to preserve and feed the pieces as best I can

As a Brazilian lover of Imbuia wood, I don’t recommend any oil based finishes for Imbuia (such as stain for example), unless indoor pieces with contact with food (cheese table for example sealed with tung oil or linseed). I recently finished a round table for our patio and the best finish found after many tries was a clearcoar of polyurethane automotive, catalised product. It did not look plastic, the wood shines through it and can withstand sun and rain.

This hard wood was used to make doors. The frame of the the door is so heavy compared to other popular woods. I had 2 doors sitting in storage for 10 years antoday decided to install as our office main entrance.