DATA SOURCE(S): 1,5,8,14,36

Common Name(s): African padauk, vermillion

Scientific Name: Pterocarpus soyauxii

Distribution: Central and tropical west Africa

Tree Size: 100-130 ft (30-40 m) tall,

2-4 ft (.6-1.2 m) trunk diameter

Average Dried Weight: 46.5 lbs/ft3 (745 kg/m3)

Specific Gravity (Basic, 12% MC): 0.63, 0.75

Janka Hardness: 1,710 lbf (7,580 N)

Modulus of Rupture: 18,380 lbf/in2 (126.7 MPa)

Elastic Modulus: 1,895,000 lbf/in2 (13.07 GPa)

Crushing Strength: 9,240 lbf/in2 (63.7 MPa)

Shrinkage: Radial: 3.1%, Tangential: 5.0%,

Volumetric: 7.9%, T/R Ratio: 1.6

Color/Appearance: Heartwood color can vary, ranging from a pale pinkish orange to a deep brownish red. Most pieces tend to start a vibrant reddish orange when freshly cut, darkening substantially over time to a reddish/purplish brown (some lighter-colored pieces can age to a grayish brown). UV-inhibiting finishes may prolong, but not prevent the gradual color-shift of this brightly colored wood. See the article Preventing Color Changes in Exotic Woods for more information.

Grain/Texture: Grain is usually straight, but can sometimes be interlocked. With a coarse, open texture and good natural luster.

Rot Resistance: Has excellent decay resistance, and is rated as durable to very durable. Padauk is also reported to be resistant to termites and other insects.

Workability: Overall padauk is easy to work, though tearout may occur when planing quartersawn or interlocked grain. Padauk turns and glues well. Filling the large open pores is usually necessary if a smooth, glass-like surface is desired. Reactive oil-based finishes, such as polyurethane, may have curing issues if the heartwood is not sealed properly beforehand.

Odor: Padauk has a faint, pleasing scent while being worked.

Allergies/Toxicity: Although severe reactions are quite uncommon, padauk has been reported as a sensitizer. Usually most common reactions simply include eye, skin, and respiratory irritation. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Widely imported as lumber in a variety of lengths and thicknesses, as well as turning and craft blanks (though with increasing levels of scarcity and trade restrictions.) Should be moderately priced for an import.

Sustainability: African padauk is listed in CITES Appendix II under the genus-wide restriction of all Pterocarpus species from Africa. Curiously, this popular commercial timber has not yet been evaluated by the IUCN and is therefore not on the Red List of Threatened Species.

Common Uses: Veneer, flooring, turned objects, musical instruments, furniture, tool handles, and other small specialty wood objects.

Comments: Padauk has a very unique reddish orange coloration, and the wood is sometimes referred to by the name vermillion. It’s moderately heavy, strong, and stiff, with exceptional stability. Padauk is a popular hardwood among hobbyist woodworkers because of its unique color and relatively low cost. It also occupies a sweet spot in density where it’s sufficiently hard and dense for higher-wear applications, yet not so dense as to be excessively difficult to work.

This wood species has a number of variant spellings and pronunciations, with a few being predominant. Padauk is the most common spelling, followed by padouk, paduk, and paduak. The most common pronunciation is pah-DUKE, followed by PAD-oak; it is sometimes mispronounced as Paducah—a city in Kentucky.

The unusual and decidedly non-Latin specific epithet soyauxii is in honor of Hermann Soyaux, a German botanist who went on several expeditions to West Africa in the 19th century. In addition to P. soyauxii, there are a handful of other less-common species sold interchangeably as padauk, such as P. osun and P. tinctorius.

Images: Drag the slider up/down to toggle between raw and finished wood.

A special thanks to Steve Earis for providing the turned photo of this wood species.

Identification: See the article on Hardwood Anatomy for definitions of endgrain features.

Porosity: diffuse porous; growth rings indistinct

Arrangement: solitary and radial multiples; mineral deposits occasionally present

Vessels: large to very large, very few

Parenchyma: diffuse-in-aggregates, winged, confluent, and banded

Rays: narrow (not visible without magnification); fairly close to close spacing

Lookalikes/Substitutes: Other African Pterocarpus species are also harvested and sold as padauk, such as P. osun, P. tessmannii, and P. tinctorius—as well as two Asian species, P. dalbergioides and P macrocarpus. Separation on a species level doesn’t seem possible based on macroscopic features. Bloodwood (Brosimum rubescens) is another popular hardwood with similar coloration that can be confused with padauk, though bloodwood is roughly 40% heavier, has slightly smaller tylosis-packed pores, and lacks the parenchyma bands seen in padauk.

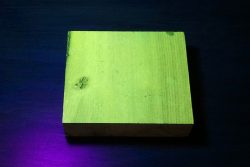

Notes: African padauk heartwood fluoresces a faint to medium yellow/orange when viewed under a blacklight

Related Content:

Just purchased a gorgeous bass from Jon Letts made entirely out of Padauk.

That is the coolest bass I’ve ever seen bro

Thanks.

He’s in the U.K.

very beautiful wood. covered American wood oil Invisible maxx pro – 8 layers

I want to use padauk for baby toy that might get chewed on. I’d obviously use a food safe finish (likely mineral oil and beeswax mix). Is it just the saw dust that is a potential allergen/irritant? Is it safe for use as a baby toy once finished?

It’s not safe for baby toy as padauk has potential to creat irritation and allergic

Hi Eric — I’m back again needing help with wood identification on another shuttle. The maker (1980s/90s) usually used one wood on the sides, a second on the tips, and a third as a decorative strip on the the tip. I’ve asked a couple of local hardwood vendors if they could identify any of the woods and the closest guess (for sides and/or tips) is African Padauk or black cherry. I didn’t think black cherry had the distinct wave patterning shown on the sides of this piece however. No one had any thoughts on the decorative strip. Do you think… Read more »

Padauk is a possibility for the outermost layer, though it’d be nearly impossible to say with certainty.

Thanks, Eric. The more I look at it the more I think it is likely black walnut. Grain patterning is very similar and the color is more of a deep brown with a bit of red tones than the red of padauk. Still not sure what the tips are but will keep evaluating!

Applied beeswax finish

Could anyone identify the wood species of this Hippo please.

impossible, from a photo like this…litterally thousands of wood species, that “look” like this….

Chakte viga ?

Hi Patrick, I have identified the wooden hippo. It is made from African Mahogany. Khaya Anthotheca of the Meliaceae family.

Gary, how is that done ? (Asking cuz I don’t know!)

thanks sincerely

Patrick

A padauk dining table I made in 1979. I remember I bought the lumber from the Dixon Bros in Boston on Albany St. for $175. I finished the wood with a urethane / turpentine/ linseed oil hand rubber finish that Art Carpenter taught me.

Has anyone had a problem with mold growing on finished Padauk pieces?

a turned african padauk

Turned and ebonized by me.

Padauk is excellent for making marimbas. The sound great.

Padauk is one of my favorite woods. The scent of cut padauk is a faint chocolate smell. The sawdust tends to be a very fine dust. The sawdust gets into everything, stains my clothes and settles on any horizontal surface like dust. But the color is so beautiful, I can’t resist using it despite the downside.

Here is a Rickenbacker base guitar style wall art that I made and one of my favorite projects using padauk.

I’m a knifemaker. Been using padauk for years. Never had a problem. Have two chef knives in service right now. Very stable, not a problem with moisture. I love the way it darkens with age. Maybe my respirator is better than others, but never had a problem with irritating dust. Orange colored clothes another subject, but it washes out. Use Watco Danish Oil finish.

I, too, am a knife maker, and I just discovered this wood when I saw a slab in a pile of wood slated for the landfill. I tried it and wow! What a pretty handle it made when paired with ebony and bone for the bolster.

I turned this Padauk bowl yesterday and I frigging love it, such a nice coloured wood

That looks awesome! I’m making a box for my grandfather’s ashes and I’m using the same wood. I really want the finish to look nice. If you don’t mind me asking, what did you use for the finish?

Love working with this wood.

That’s really dark, did you stain it?

Yes it was to red for what we wanted

Used Padauk for the red stripes in my American Flag bar top, beautiful and easy to work with. ???

It’s a beautiful piece of art! :O

Had posted this on the ‘bloodwood’ page, but that top bat has padauk as the stripes! Makes a great red for this star spangled bat :)

This is my first time using Padang. My wife and I are making a keepsake box for a friend of our for her 70th birthday. We are really enjoying the way this project is turning out. Will make other projects with this combined with other woods.

I am using Paduak as my grip-cap and fore-end tip material on a custom Weatherby vanguard stock. The reason I came to this site is because although I love the smell, it feels like I have fiberglass in my throat and lungs when I cut it. I wear a mask that seals well but maybe I need to step up my game. The color is phenomenal when a Tru-oil finish is applied to the wood. Definitely worth the slight irritation.

For the life of me, I can’t place the smell when I run Padauk through my table saw… for about 10 seconds, it smells like… freshly made chocolate? driving me nuts. Other than that, I love using it for a bit of colour in my cutting boards (edge grain), and I’ve made a toy truck for my grandson. I finish with 3 coats of Osmo Top Oil and have had no problems at all. I love this wood with Maple, Walnut, Zebrawood etc.

Chocolate for sure. I often use it with mahogany. The warm colors complement well. I just don’t like the powder when cutting Padauk. I sticks to and stains everything.

Sanding Padauk leaves a wooder looking like he or she has been at a bag of Cheetohs.

I always thought it smelled like old crayons.

I’m halfway through building an African Padauk acoustic guitar. Observations so far: Side bending requires more heat than some woods, but it scorches easily. I had to run the sides through 2 heat cycles in the bending machine and they still sprung back fiercly. It is also prone to splitting, so you have to be careful about forcing them into a mold. Next time I would thickness them down to 0.08″ instead of 0.09″. The pigment in the sanding dust is amazingly potent, and very soluble in water and alcohol. I’ve abandoned plans for curly maple binding, which would end… Read more »

I love the wood for its color, but when I cut it on my table saw, the saw dust is like powder, goes everywhere and stains my clothes. Beware. Same thing when I use a random orbital sander. I have used it on cutting boards, but mostly for serving boards rather than chopping or cutting boards. Also, the smell of freshly sawn padauk is very pleasant.

Ditto for the dust; I recently made kitchen tools using padauk. Once it got on the belt sander, the sawdust flew everywhere, more so than the other woods I was using. I now have a very pretty padauk-stained concrete floor.

Agreed on all points. I prefer it on serving boards over cutting boards because the grain is quite open especially on the face grain.

i put it in my longboard, still a work in progress but it should look good with my beech

I don’t use padauk in my woodworking, but have used the sawdust in alcohol to dye paper. I am testing for light fastness in paper but assuming it is fugitive, as it is in wood. Too soon to say, but so far surprisingly good after 6 months. Creates a beautiful salmon pink that is hard to describe. For those using alcohol based polish or varnishes on padauk: to keep it from bleeding I strongly suggest you experiment with egg white as a sealer. Don’t water it down, just remove the yoke and brush the white on. There are more complicated… Read more »

Thank you, Jim! I was looking for information about using isopropyl for FP for a while. All of that information was helpful :)

You only have to be concerned about Glyphosphate if your alcohol is made from corn. Buy vodka or any other clear liquor made from wheat, or potatoes or whatever, and you’re fine. (In Europe this isn’t much of a problem since mist alcohol isn’t made from corn).

Lucky we have 99% ethyl alcohol available. No methyl alcohol in it. Expensive, but it’s worth its price. Dissolves shellac beautifully.

What is the white “mold” on the surface of my Padauk? It wipes off. Will it come back under my finish?

I think you are referring to what is called “mill glaze”. Happens with this wood often when you run it through a planer. Been a while since I worked with Padauk but I don’t remember it being of concern once the project was finished.

it’s a fungus and it won’t come back after finishing the piece,, you better finish the insides and all exposed surfaces of it

look in:

https://www.mimf.com/library/A_failed_attempt_to_identify_a_mold_that_seems_to_grow_on_many_pieces_of_padauk__Pictures_-07-23-2006.html

I have the same problem. I made a tea box and it grows the mold like crazy. I sealed the wood really well and put polyurethane on it and it still grows. I washed it off with diluted bleach and resealed it with a mother coat of poly but no luck! Very frustrating because it is very beautiful. I live in florida but the box is in air-conditioned room all the time.

Does anyone know hoe to get rid of it? You have to kill the spores that may survive the bleach.

I have a Mali billiards stick whose butt end is made from Padauk wood…it is a gorgeous deep red-brown color and has held its beautiful color for over 30 years. Love the stick and the look…named her “old faithful” due to years of consistent play.

I make crosses and trivets and they are beautiful. I give to friends and relatives and they are amazed at how they look and can’t truly express how much they appreciate them.

can kit be used to make a smokeable tobacco pipe?

Can Padauk be used in a cutting boad

Padauk has very large open pores, so it would depend on what the cutting board is going to be used for. Some would say that you shouldn’t use these types of porous woods for things like cutting boards used for meats, as it will trap bacteria in these tiny holes.

Padauk Spoon, finished with Tung Oil.

What did you use for the finish?

Can you eat out of those bowls? Like Soup?

Beautiful!

This is our first time using this wood at the request of a customer and I am surprised at how red it turned out to be! It is almost unbelievable, like they were stained, but this is natural. These have 2 coats of CA as a sealer and 12 coats of tru-oil. I hope they stay this red!

What a find and incredibly well done!

On the odor section, every time I have worked with Padauk, I have found it to have a very strong pepper-like scent, not a pleasing scent as the article suggests. I still love the wood though!

Has a slight rose scent. Not much unlike some dalbergias.

JMO

If have wood allergies, skin irritant

A warning to anyone who incorporates padauk into a project that also includes a lighter colored wood such as maple. When choosing a finish, avoid shellac. The pigment in padauk is alcohol soluble and will bleed a pinkish smear all over the place. I discovered this the hard way.

This is very true. Though if you’re a die-hard shellac fan like me, you can still usually get away with combining the two woods using shellac if you’re careful. What I do is use a very light mix (1 pound cut) of shellac, and pad it on very lightly for the first coat. If you wipe along the direction of the wood edge, you should avoid smearing any coloration into the surrounding wood. Once the initial coats are dry, the wood should be sealed and you can then finish as usual.

I decided to go with padauk and yellowheart for a chess board (3-1/4″

squares). Both produced very fine saw dust (the padauk will stain

clothes…) and cuts cleanly. Glued up with biscuit joints worked

nicely.

I recently bought a piece of Padouk to make a guitar with. Unfortunately I had it sent to my luthier, and I’m not sure the what the scheduling will be. I’m sure he’ll get me close up pics before work begins on the neck – I’ll post pictures when I get them.

it’s getting close

Hey Ed Here are pics of a Padauk guitar I just Finished. Featuring a Maple Stripe and Yes it is a Hollow Body.

Hi Guys,

I’m looking for a sustainable, strong, stable timber for the construction of a timber frame house. All timber will be exposed to the Cape Town elements. I’m able to get 76mm in long 4.5m lengths so this will do for the exposed structural beams, rafters etc. Does anyone think African Padauk will do the job.

Cheers

Paduak is an excellent outdoor wood in my opinion I expose the raw wood to new jersey weather for years with little problem, and it is available in large sizes however here in the US its difficult and expensive to get a hold of

What do you mean br viverbit in CA suoer glue?

Looking at using padauk for decking on my sailboat. I keep the boat stored outside in Elliott Bay Marina in Seattle year around and sail often even in our rainy Seattle days. Curious as to this wood being able to withstand the sail spray and weather. I could make a cover to use while not sailing. But if I don’t need to then I won’t.

Thanks

Im probably late with this but here goes. I used a piece of padauk edge trimmed from a 4qtr board for a tiller extension. I planed the corners out with a krenov style jointer plane I built and worked into a 4 ft long semi round taper with a spokeshave for a tiller extension on my sloop. Braided a turks head end cap, wrapped forward 10 in. and did 3 more turks head rings tight against the wrap. A largish between 2 smaller. Oiled the bare remainder with interior watco and thats it. Needs oil again. Its been on 3… Read more »

Most oily tropical woods are pretty resilient that way. The only thing that is for certain is that the sunlight is going to turn the padauk into a generic brown color very quickly, especially in your application.

I started building acoustic guitars a couple of years ago, the best so far has back and sides made from padauk. I used 6 hour epoxy as a sealer and pore filler, which, it turns out, kept the color a beautiful deep red. It is brittle, loves to split, but will bend like cardboard for guitar sides if evenly heated to about 310 degrees (a little hotter than most guitar woods). The dust gets everywhere and will permanently stain clothes. If you hold up a board, hit it with a knuckle, and listen, (the “taptone”), it has very bright, almost… Read more »

I chose Paduak for a knife handle because of it’s striking contrasts of colors. However, shortly after finishing I found like TREVOR; the coloring all merged into a bland uniform look.

I think sealing would be a good idea.

Unfortunately the color of African padauk doesn’t last long, in a few days the wood darkens to a deep redish-brown, however, if you vover it in CA super glue it stays bright orange for years to come.

Padauk is the first true exotic I’ve worked with and I love the colors and bands of various shades in the wood BUT I found out quickly that tools needed to be wiped and different sheets of sand paper need to be used as the sawdust is very fine and stains hands, clothes, and can be imparted on other woods during sanding.

I am currently making an end grain cutting board from hard maple and pad auk. I chose the pad auk over Purple Heart because the end grain looked better. After milling the padauk, I am not so sure. I found the saw dust extreme and am wondering if my selection of padauk was a good choice.

Ian interested in any feedback or comments

Steve Thomas

padauk is a beautiful red-orange to bright orange hardwood, my first (exotic) pen was made of padauk.

I decided to go with padauk and yellowheart for a chess board (3-1/4″ squares). Both produced very fine saw dust (the padauk will stain clothes…) and cuts cleanly. Glued up with biscuit joints worked nicely.

I think it would be fine to use Padauk for a pepper mill. One thing to keep in mind is that a lot of woods cause allergic reactions, but that’s mainly from inhaling the wood dust itself. Very few woods are in and of themselves poisonous or toxic. (Yew and Sassafras come to mind in this category.) Also, I would stay away from spalted woods, which may have fungus or mold still present. I understand the concern to finish the inside, but I think it may be overkill. The finish itself, being closed off in a small sealed container, may… Read more »

I am contemplating turning a pepper mill from Padauk. Is that wood safe to use here? If so, should I finish the inside and with what?