|

Common Name(s): Oregon Myrtle, California Bay Laurel, Pepperwood, Myrtlewood

Scientific Name: Umbellularia californica Distribution: Coastal regions of southwest Oregon and central California Tree Size: 50-80 ft (15-24 m) tall, 2-3 ft (.6-1 m) trunk diameter Average Dried Weight: 40 lbs/ft3 (635 kg/m3) Specific Gravity (Basic, 12% MC): .51, .63 Janka Hardness: 1,270 lbf (5,650 N) Modulus of Rupture: 9,700 lbf/in2 (66.9 MPa) Elastic Modulus: 1,225,000 lbf/in2 (8.45 GPa) Crushing Strength: 5,640 lbf/in2 (38.9 MPa) Shrinkage: Radial: 2.8%, Tangential: 8.1%, Volumetric: 11.9%, T/R Ratio: 2.9 |

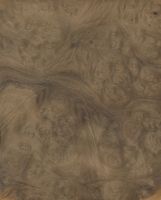

Color/Appearance: Heartwood color can be variable, from light orangish brown to gray or olive, sometimes with darker streaks present. Pale sapwood is usually well defined. Figured grain patterns (curly, mottled, burl) are not uncommon.

Grain/Texture: Grain can be straight, irregular, or wavy. Has a fine uniform texture with low natural luster.

Endgrain: Diffuse-porous; solitary and radial multiples; medium to large pores in no specific arrangement, few to moderately numerous; tyloses mineral/gum deposits occasionally present; parenchyma vasicentric; narrow rays, spacing normal.

Rot Resistance: Heart rot is common, and various decay fungi are known to infect living trees. Poor insect resistance.

Workability: Fairly easy to work, though tearout can occur on pieces with figured grain. Has a tendency to burn during drilling and routing, and appropriate speeds and sharp cutters are recommended. Turns, glues, and finishes well.

Odor: Has a strong, spicy odor when being worked.

Allergies/Toxicity: Although severe reactions are quite uncommon, Myrtle has been reported to be a skin irritant as well as a sensitizer. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Occasionally available as smaller lumber or veneer. Per board-foot prices are among the highest for domestic hardwoods. Figured pieces and burls are very expensive.

Sustainability: This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species.

Common Uses: Veneer, cabinetry, fine furniture, musical instruments (guitar backs), interior trim, gunstocks, turned objects, and other small specialty items.

Comments: Known by a wide variety of local or regional common names. Technically not related to true myrtle (Myrtus genus), Myrtle is the only species in the Umbellularia genus, and is technically in the Lauraceae (Laurel) family. It’s sometimes called California Laurel, and the leaves have a pungent flavor similar to Bay Laurel (Laurus nobilis).

The wood itself has poor strength values for its weight, and is typically used for more aesthetic purposes, rather than in applications where strength is important.

None available.

Scans/Pictures: A special thanks to Ken Forden for providing the wood sample of this wood species.

I poured through the identification section because my dad marked this as “Bay Laurel” and I couldn’t find it then I matched it to Myrtle photos and now I’m here lol! Mine is pretty white and plain with grey streaks. Funny enough it’s riddled with some sort of insect holes. Never seen anything like it. I was told carpenter bees but I dont think so, tightly packed sawdust…best I can guess is bostichidae or False powder post beetle.. What do you all think?

I grew up surrounded by Myrtlewood in Coos County, Oregon. I have since lived near California laurels, and they seem to me to be very similar, but definitely different trees. In particular, crushing the leaves of the Oregon tree yields a much more pungent, and (to me) attractive scent that the CA laurel leaves.

Around Portland myrtle lumber is most commonly found as highly figured sapwood like so, heartwood is pretty rare in my experience.

Breedlove Guitars has a entire line of guitars made from Myrtlewood, I’ve owned one for almost 5 years and its tone is amazing

Good luck on your build, the back that you posted is beautiful

Any opinions on using Myrtlewood for chopsticks?? Putting lacquer on them or not to preserve them for longer?? Any advice appreciated!! TIA!!

My experience is turning bowls of this figured wood, and using chopsticks daily made from several types of hardwood. If careful to select dry straight wood, it would be effective for chopsticks. No need to add lacquer or any finish, but a if finish is desired, better to use Reactive type (ie varnish and or drying oils) rather than Evaporative orWater-base finishes. See details at https://www.overdrive.com/media/530924/flexner-on-finishing

I love Oregon Myrtle, One of my builds using it !!

California Bay Laurel trees are abundant in my area. Here’s a crotch piece I picked out of a firewood pile to turn an end-grain live surface bowl.

I was fortunate enough to purchase a sawn log of Myrtle a few years ago. After drying, one of the projects that I used this beautiful wood for was a set of night stands. I am currently working on the dresser to match.

Some pieces of Myrtle have very rich tones that pop when finished. Here’s a coffee table made with a top of re-sawn book-matched Myrtle sourced from Bandon Oregon. The top rails and legs are Cherry, with Ambrosia Maple corners.

My property is surrounded with Bay Laurel. I have lots of experience working with this wood. Once dried, It’s quite stable, as any other wood. I made acoustic guitar body, and neck. with it. After 5+ years, there’s no signs of movement. I also find it very strong for it weight, contrary to what is said in the comments section above. Much more than black walnut. The native Indians used them to make bow.

I knew an oboe maker in Oregon who produced a baroque oboe made of Oregon myrtle. At first she was quite pleased with the result, as the instrument looked beautiful, played well and was amazingly light in weight. But, within a year the wood proved to be so unstable that the instrument had grown completely out of tune with itself. So that experiment was never repeated!

Hi there,

Any chance you know of woods she tried that DO work? I’m making baroque oboes and would love to find a suitable domestic wood that someone actually sells!

This maker would use maple for test models — she said her use of it was like how a dressmaker would use muslin. But excellent bassoons are made of maple, so there’s certainly nothing wrong with it.