DATA SOURCE(S): 1,2,6,14,36

Common Name(s): Limba, korina, afara, black limba, white limba

Scientific Name: Terminalia superba

Distribution: Tropical western Africa

Tree Size:65- 100 ft (20-30 m) tall,

5-7 ft (1.5-2.2 m) trunk diameter

Average Dried Weight: 35 lbs/ft3 (555 kg/m3)

Specific Gravity (Basic, 12% MC): 0.43, 0.56

Janka Hardness: 670 lbf (2,990 N)

Modulus of Rupture: 12,510 lbf/in2 (86.2 MPa)

Elastic Modulus: 1,520,000 lbf/in2 (10.49 GPa)

Crushing Strength: 6,580 lbf/in2 (45.4 MPa)

Shrinkage: Radial: 4.3%, Tangential: 6.3%,

Volumetric: 10.8%, T/R Ratio: 1.5

Color/Appearance: Heartwood is a light yellowish to golden brown, sometimes with grey to nearly black streaks and veins. Wood with such darker figuring is referred to as black limba, while plain unfigured wood is called white limba. Sapwood is a pale greyish to yellowish brown, not clearly demarcated from the heartwood. Overall color tends to darken with age.

Grain/Texture: Grain is straight to slightly interlocked, with a uniformly coarse texture. Moderate natural luster.

Rot Resistance: Rated as non-durable, and also susceptible to insect attack.

Workability: Easy to work with both hand and machine tools. Contains a small amount of silica, but blunting effect on cutters is usually small. Glues and finishes well.

Odor: Limba has a mild odor while being worked.

Allergies/Toxicity: Although severe reactions are quite uncommon, limba has been reported to cause skin and respiratory irritation, as well hives, asthma-like symptoms, and bleeding of the nose and gums. Splinters also tend to become infected and take longer than usual to heal. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: In relatively good supply and available in board and veneer form. Prices for white limba are moderate for an imported hardwood, though figured wood such as the more popular black limba is more expensive.

Sustainability: This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species. Although the species has been cultivated on plantations for timber, wild supplies seem to have diminished in some regions, such as the Republic of the Congo.[1]Lemmens, R. H. M. J., Louppe, D., & Oteng-Amoako, A. A. (2012). Timbers 2 (Vol. 7, p. 631). PROTA. Its unevaluated status by the IUCN is an unfortunate omission.

Common Uses: Veneer, plywood, furniture, musical instruments (primarily electric guitar bodies), and turned objects.

Comments: Despite the black-and-white difference in names, both black limba and white limba come from the same tree species, Terminalia superba.

In veneer form, this wood goes by a number of commercial names, such as afara, frake, korina, and ofram. In addition to its decorative use in veneer, limba has a reputation for possessing good tonal qualities and is frequently used in electric guitar bodies (marketed under the name korina).

Images: Drag the slider up/down to toggle between raw and finished wood. The first sample shows black limba, while the second is an example of unfigured white limba.

A special thanks to Steve Earis for providing a veneer sample of white limba.

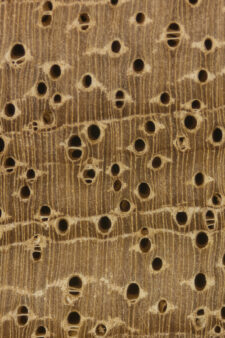

Identification: See the article on Hardwood Anatomy for definitions of endgrain features.

Porosity: diffuse porous; in some samples growth rings are subtly discernible due to decrease in pore frequency in latewood

Arrangement: solitary and radial multiples

Vessels: medium to very large, very few; tyloses occasionally present

Parenchyma: vasicentric, winged, and confluent

Rays: narrow width, normal to close spacing; rays not visible without hand lens

Lookalikes/Substitutes: Can be confused with the closely related idigbo (Terminalia ivorensis). However, despite the similar appearance and weight, limba very frequently has elongated winged parenchyma, while idigbo has more modest parenchyma that’s usually just vasicentric, or mildly lozenge and confluent.

Notes: None.

Related Content:

Stained Limba baton.

Great wood to work with. Few drawbacks though. First it is porous and they come. I can blow compressed air all the way thru a 2-inch thick piece. I have found it necessary to seal end grain boards with resin to seal up those deep pores. Also it tends to have silica crystals in it. You can literally see the shiny microscopic crystal shining. Wreaks havoc on sand paper, blades and bits. But its my go-to wood..

Ryan Bates

Put that wood in a high-pressure chamber and all of that silica will be forced down into the wood, my system creates about a 1000 PSI and pushes silica deep into the wood, it also makes the wood easier to work with.

The sheen of black limba turned pieces is so beautiful, but it’s good to hear the reality of turning it.

Would this wood be recommended 4 floating shelves in a kitchen?

did anyone reply about this? we are currently contemplating the same thing! We would want to stain it slightly darker if possible.. any advice on what to use appreciated!

I work with Limba all the time. It would be fine for shelves.

Yes you can use it for that. I used solid glass tubes that went into the wall and the other end went into the wood.

I’m just finishing a “Hauser” classical guitar out of “Black Limba” and it’s beautiful! I have some sanding and finishing, so I haven’t strung it yet, but she’s already “singing to me!

Interesting. Do you have a clue about how it behaves both sonically and structural?

Korina is legendary for it’s tonal properties in guitar making. Gibson used them during the 50s to produce some of it’s Explorers and Flying Vees, which are highly sought out as collectors, sometimes ranging well into the mid-six figures.

For sure. But I’m particularly curious about how it behaves in a classical guitar. I have some highly figured B&S sets here waiting for a project, so someday I’ll give it a try.

Limba is very close to Mahogany in terms of musical instruments from my experience. Seems to sound almost the same and works similar with tools. Lovely wood! I think of it as a more exotic form of Mahogany.

I’m presently building an acoustic electric guitar and was wondering if you have done any guitars yet with this wood. How do they sound? How do they take french polishing?

Looks like my image didn’t load, so here’s another attempt.

Maybe check the file size? Sometimes the file is too large.

OK, third time’s the charm.

I love your site, Eric and visit it at least once a day. Kudos for creating this amazing online resource. I would to add to your Workability notes: Black Limba turns well and takes finish easily. Here’ a recent bowl finished with polished beeswax.

Used it for the frame of my American Flag bar along w Curly maple and Padauk… .. absolutely beautiful and easy to work with.

It’s amazing how many lumber yards never heard of it. It was very common in the woodworking shops in Kansas schools. Made great gun racks.?

I have a beautiful Taylor 414ce LTD 2019 that is Black Limba back and sides. Thought I’d share. Thanks for the article.

That’s pretty unique. I bet the tone is incredible.

Wow!!!

Beautiful!!!

Plays?

Sounds?

Sustain?

Very Beautiful Guitar…

Drooling…

Black Limba cutting board. Bordered by Ziricote and Zebra / Wenge stripes

The Black Limba grain patterns are hypnotizing. We’re looking at book-matched end-grain cuts, right? I’m seeing the Grinch Who Stole Christmas (top center) flanked by bats on his left and right. A flying monkey from the Wizard of Oz (top right). Two screaming meerkats on the bottom row.

A very creative use of color & grain variation. Well done!

Bookmatched end grain — Huh. That thought never occurred to me. Thanks to Ryan for demonstrating it, and Stephen for explaining it.

Haha. Thanks for the colorful explanation. I look at this board everyday and now I see the grinch every time.

I have an Epiphone Flying V “1958 Korina V” and it’s beautiful. The body is light as a feather and the tone is magnificent.

I had a bass body custom built out of limba (black korina). The wood takes die really well and has great tone!

Thanks for the information. I made a gun cabinet and black powder pistol box out of this wood back in 1971. That was my 10th grade project for wood shop.