|

Common Name(s): Sitka Spruce Scientific Name: Picea sitchensis Distribution: Northwestern North America Tree Size: 130-160 ft (40-50 m) tall, 4-6 ft (1.2-1.8 m) trunk diameter Average Dried Weight: 27 lbs/ft3 (425 kg/m3) Specific Gravity (Basic, 12% MC): .36, .42 Janka Hardness: 510 lbf (2,270 N) Modulus of Rupture: 10,150 lbf/in2 (70.0 MPa) Elastic Modulus: 1,600,000 lbf/in2 (11.03 GPa) Crushing Strength: 5,550 lbf/in2 (38.2 MPa) Shrinkage: Radial: 4.3%, Tangential: 7.5%, Volumetric: 11.5%, T/R Ratio: 1.7 |

Color/Appearance: Ranges from cream/white to yellow; heartwood can also exhibit a subtle pinkish red hue in some instances. Sapwood not clearly demarcated from heartwood. Some pieces can exhibit a special grain pattern called bearclaw—vaguely resembling the scratches of a bear’s claws.

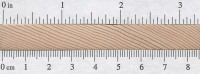

Grain/Texture: Sitka Spruce has a fine, even texture, and a consistently straight grain.

Endgrain: Medium sized resin canals (larger than other spruce), sparse to numerous and variable in distribution; solitary or in tangential groups of several; earlywood to latewood transition gradual, color contrast medium; tracheid diameter medium-large.

Rot Resistance: Heartwood is rated as being slightly resistant to non-resistant to decay.

Workability: Easy to work, as long as there are no knots present. Glues and finishes well, though it can give poor (blotchy and inconsistent) results when being stained due to its closed pore structure. A sanding sealer, gel stain, or toner is recommended when coloring Spruce.

Odor: No characteristic odor.

Allergies/Toxicity: Although severe reactions are quite uncommon, Spruce in the Picea genus has been reported as a sensitizer. Usually most common reactions simply include skin irritation and/or respiratory disorders. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Construction grade spruce is cheap and easy to find. However, old growth and/or quartersawn clear pieces—free from knots—can be more expensive. Quartersawn billets of instrument-grade Sitka Spruce can easily exceed the cost of most all domestic hardwoods in terms of per board-foot cost.

Sustainability: This wood species is not listed in the CITES Appendices, and is reported by the IUCN as being a species of least concern.

Common Uses: Lumber, boxes/crates, furniture, millwork, aircraft components, musical instrument soundboards, boatbuilding (masts and spars), wind turbine blades, and virtually any application where a wood material with a good strength-to-weight ratio is needed.

Comments: Sitka Spruce has an outstanding stiffness-to-weight ratio, and is available in large, straight-grained pieces, lending this timber to a wide range of commercial uses.

Scans/Pictures: A special thanks to Steve Earis for providing the turned photo of this wood species.

|

|

|

|

|

I see that Sitka Spruce is used in aircraft components. Though, no idea just what. I used to be a Missile Technician in the US Navy. We were taught that the third stage rocket motor of the Trident I, submarine -launched ballistic missile, which is housed inside the nose cone, rolls out of its housing, after it has been expended, on wheels made from Sitka Spruce. But we were never taught exactly what characteristics that Sitka Spruce has, made it so desirable, specifically. I’ve read, on my own initiative, that Sitka Spruce that is grown on the north side of… Read more »

Yes, with softwoods, generally the slower the wood grows, the better the lumber in nearly every way (strength, hardness, stability). That’s because, among other things, the annual growth cycles—and by extension, the annual rings—become more compressed, resulting in a higher overall percentage of the denser latewood (i.e., the darker-colored “lines” of softwood lumber that form the annual rings).

Great information…we are trying to make reedboard of reed organ lets see