Common Name(s): Cocobolo (many variant spellings, such as cocabola or cocobola)

Scientific Name: Dalbergia retusa

Distribution: Central America

Tree Size: 45–60 ft (14–18 m) tall,

1.5–2 ft (.5–.6 m) trunk diameter

Average Dried Weight:AVERAGE DRIED WEIGHT

Density is the measurement of a wood’s weight per unit volume. Here, "dried weight" specifically refers to wood at 12% moisture content, and values are given in pounds per cubic foot and kilograms per cubic meter. Also keep in mind that density commonly varies by +/- 10% from the average.

Click on the link "Average Dried Weight" for more details. 68.5 lbs/ft3 (1,095 kg/m3) Very High WEIGHT TIERS

Extremely Low: 0+ kg/m3

Very Low: 420+ kg/m3

Low: 520+ kg/m3

Medium-Low: 620+ kg/m3

Medium: 730+ kg/m3

Medium-High: 840+ kg/m3

High: 960+ kg/m3

Very High: 1,080+ kg/m3

Extremely High: 1,200+ kg/m3

Tiers are based on CSIRO provisional strength groupings (SD1-SD8) based on density.

Janka Hardness:JANKA HARDNESS

This test measures a wood’s resistance to indentation, and is the pounds of force (or Newtons) required to embed a .444" (11.28 mm) diameter steel ball halfway into the wood. Values are for side grain, measured at 12% MC.

Click on the link "Janka Hardness" for more details. 2,960 lbf (14,140 N) Very High JANKA HARDNESS TIERS

Extremely Low: 0+ N

Very Low: 2,050+ N

Low: 3,150+ N

Medium-Low: 4,480+ N

Medium: 6,280+ N

Medium-High: 8,380+ N

High: 11,080+ N

Very High: 14,000+ N

Extremely High: 17,450+ N

Tiers are derived from CSIRO provisional strength classifications (SD1-SD8) in conjunction with the USDA's estimated hardness based on density.

Modulus of Rupture:MODULUS OF RUPTURE

Sometimes called bending strength, this test measures a wood’s strength before breaking (i.e., rupturing). Values are given in pounds of force per square inch and megapascals, measured at 12% MC.

Click on the link "Modulus of Rupture" for more details. 22,910 lbf/in2 (158 MPa)* Extremely High MOR TIERS

Extremely Low: 0+ MPa

Very Low: 45+ MPa

Low: 55+ MPa

Medium-Low: 65+ MPa

Medium: 78+ MPa

Medium-High: 94+ MPa

High: 110+ MPa

Very High: 130+ MPa

Extremely High: 150+ MPa

Tiers are based on CSIRO strength classifications (SD1-SD8).

Elastic Modulus:MODULUS OF ELASTICITY

This test measures the wood’s level of deformation when under a given load. Higher values indicate less deformation (i.e., stiffer). Values are given in pounds of force per square inch and gigapascals, measured at 12% MC.

Click on the link "Elastic Modulus" for more details. 2,712,000 lbf/in2 (18.7 GPa)* Very High MOE TIERS

Extremely Low: 0+ GPa

Very Low: 7.9+ GPa

Low: 9.1+ GPa

Medium-Low: 10.5+ GPa

Medium: 12.5+ GPa

Medium-High: 14.0+ GPa

High: 16.0+ GPa

Very High: 18.5+ GPa

Extremely High: 21.5+ GPa

Tiers are based on CSIRO strength classifications (SD1-SD8).

Crushing Strength:CRUSHING STRENGTH

Also called compression strength, this test measures the maximum stress sustained before failure. Force is applied parallel to the grain (producing stress akin to chair legs). Values are given in pounds of force per square inch and megapascals, measured at 12% MC.

Click on the link "Crushing Strength" for more details. 11,790 lbf/in2 (81.3 MPa)* Extremely High CRUSHING STRENGTH TIERS

Extremely Low: 0+ MPa

Very Low: 30+ MPa

Low: 36+ MPa

Medium-Low: 41+ MPa

Medium: 47+ MPa

Medium-High: 54+ MPa

High: 61+ MPa

Very High: 70+ MPa

Extremely High: 80+ MPa

Tiers are based on CSIRO strength classifications (SD1-SD8).

*values from tentative strength group assessment per South American Timbers[1]Berni, C. A., Bolza, E., & Christensen, F. J. (1979). South American timbers: The properties, uses, and characteristics of 190 species. p. 86. Commonwealth Scientific and Industrial Research … Continue reading

Shrinkage:SHRINKAGE

These values represent the percentage change in radial and tangential faces of the wood—as well as the total (volumetric) shrinkage—as the moisture content goes from green (maximum) down to oven-dry (minimum), approximating the wood's stability with changes in humidity. T/R ratio helps to estimate the uniformity of the shrinkage across different wood faces.

Click on the link "Shrinkage" for more details. Radial: 2.7%, Tangential: 4.3% Low SHRINKAGE TIERS

Very Low: 0%+

Low: 3.6%+

Medium: 5.1%+

High: 6.6%+

Very High: 8.1%+

Tiers are based on tangential shrinkage (green to oven-dry) from CSIRO shrinkage classifications (1-5).

Volumetric: 7.0%, T/R Ratio: 1.6

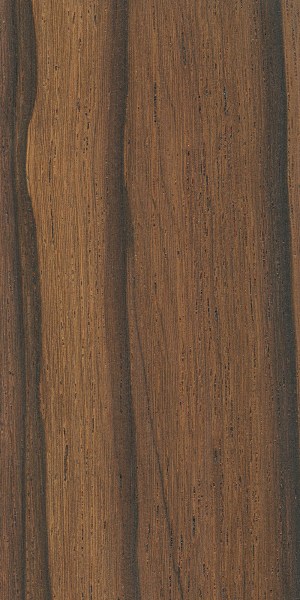

Color/Appearance: Cocobolo can be seen in a kaleidoscope of different colors, ranging from yellow, orange, red, and shades of brown with streaks of black or purple. Sapwood is typically a very pale yellow. Colors are lighter when freshly sanded/cut, and darken with age; for more information, see the article on preventing color changes in exotic woods.

Grain/Texture: Grain is straight to interlocked, with a fine, even texture. Good natural luster.

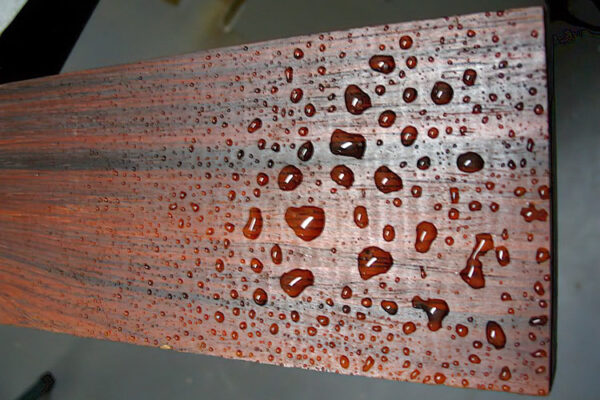

Rot Resistance: Rated as very durable, and also resistant to insect attack. Its natural oils are reported to give it good resistance to degrade from wet/dry cycles.

Workability: Due to the high oil content found in this wood, it can occasionally cause problems with gluing. Also, the wood’s color can bleed into surrounding wood when applying a finish, so care must be taken on the initial seal coats not to smear the wood’s color/oils into surrounding areas. Tearout can occur during planing if interlocked grain is present; the wood also has a moderate blunting effect on cutting edges/tools due to its high density. Cocobolo has excellent turning properties.

Odor: Cocobolo has a distinct spice-like scent when being worked, which some find unpleasant: though it has been used in at least one women’s perfume.

Allergies/Toxicity: Notoriously allergenic. Reported as a sensitizer; can cause skin, eye, and respiratory irritation, as well as nausea, pink-eye, and asthma-like symptoms. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Cocobolo is in limited supply, and is also in relatively high demand, (for ornamental purposes), and is likely to be quite expensive. Prices should compare similarly to other rosewoods in the Dalbergia genus.

Sustainability: Cocobolo is listed on CITES appendix II under the genus-wide restriction on all Dalbergia species—which also includes finished products made of the wood (though finished items under 10 kilograms are exempted). It is also listed on the IUCN Red List as vulnerable due to a population reduction of over 20% in the past three generations, caused by a decline in its natural range, and exploitation.

Common Uses: Fine furniture, musical instruments, turnings, and other small specialty objects.

Comments: One of today’s most prized lumbers for its outstanding color and figure—yet also one of the most infamous for its difficulty in gluing, and its tendency to cause allergic reactions in woodworkers.

Images: Drag the slider up/down to toggle between raw and finished wood.

A special thanks to Steve Earis for providing turned photos of this wood species.

Identification: See the article on Hardwood Anatomy for definitions of end grain features.

Porosity:POROSITY

Specifies the overall pore structure (ring-porous, semi-ring-porous, or diffuse porous), and notes if annual growth rings may still be seen even for diffuse porous hardwoods.

Click on the link “Porosity” for more details. diffuse porous; growth rings sometimes discernible due to marginal parenchyma and a decrease in diffuse parenchyma

Arrangement:ARRANGEMENT

Describes the more individual pore arrangements found throughout the end grain surface, such as solitary, multiples, chains, clusters, etc.

Click on the link “Arrangement” for more details. solitary and radial multiples

Vessels:VESSELS

Describes the relative size and frequency of the pores (vessels), as well as any contents found in the pores, such as tyloses, colored mineral deposits, etc.

Click on the link “Vessels” for more details. medium to very large, few to very few; reddish brown deposits common

Parenchyma:PARENCHYMA

Describes the pattern(s) of the parenchyma cells seen on the endgrain, such as vasicentric, aliform (winged or lozenge), confluent, and banded.

Click on the link “Parenchyma” for more details. diffuse-in-aggregates, vasicentric, and banded (marginal)

Rays:RAYS

Describes the relative width and frequency of the rays (appearing as thin vertical lines on the endgrain), as well as a note on if these rays are visible with/without magnification.

Click on the link “Rays” for more details. narrow, normal to close spacing; rays generally not visible without magnification

Lookalikes/Substitutes: Pau ferro (Machaerium spp.) has a very similar overall appearance that can also be confused with (or substituted for) cocobolo. Cocobolo can be separated from lookalikes based on it’s large and very infrequent pores, averaging only about 3-6 pores per mm2.

Notes: Can bear a similarity to many different genuine rosewood species.

Related Species:

Related Content:

References[+]

| ↑1 | Berni, C. A., Bolza, E., & Christensen, F. J. (1979). South American timbers: The properties, uses, and characteristics of 190 species. p. 86. Commonwealth Scientific and Industrial Research Organization, Division of Building Research. |

|---|

I have a bagpipe chanter from the late 1950’s to early 1960’s I believe is Cocobolo. Lots of color, beautiful wood. Do you think I am correct in the type of wood? Under a black lite, it looks much different that any other wood I have, Great website, thanks!

A box in cocobolo

Cocobolo baton.

does this wood steam bend well or not please steven.

I have a Backun clarinet made from cocobolo wood. It is an amazing clarinet, the wood helps the sound resonate a lot more. Its a beautiful color and I recommend cocobolo wood for a solo clarinet or a wind symphony clarinet.

I have a cocobola baton from my dad when he was a cop in the 70’s.

I recently started using it I’m my martial arts practice and had to sand the finish off, ( as it was to slick).

Should I leave it natural or apply an oil?

Tom Sacco September, 25, 2018 – reply

Why is some cocobolo just purple and others have the yellow, red, brown, purple, black, ECT.

Thank you,

I’m currently in the process of having a pool cue made with Cocobolo. One of my other custom cues was made with ebony going into purple heart. It hits great. So, like getting tattoos, I had to get another. I’m having cocobolo going into purple heart. I don’t want to readjust my game by changing the purple heart. And since cocobolo is very similar in structure to ebony, I figure it should work. After paying for it in full upfront, I can’t wait to see it completed….let alone to use it. If anyone has images of their own cocobolo custom… Read more »

is this referred as Genuine Rosewood? My friend has these Rosewood from Brazil they were cut maybe 20 years ago and brought to Canada.

If you have rosewood from Brazil that they are calling “genuine rosewood” then I would assume they are referring to Brazilian Rosewood (Dalberia nigra).

I have a wall clock made out of cocobolo wood. Two layers of shellac was applied but what kind of finish can be used now to complete the project and give it a more glossy look? Would appreciate any advice.

Once you’ve sealed the wood with shellac, you can use any number of finishes. If it isn’t going to get too much wear and handling, you could try to just top coat with shellac too — it is naturally quite glossy. Otherwise polyurethane or lacquer are both glossy as well.

I was given a piece of wood that I cannot quite identify. From all the woods I know, it resembles Cocobolo the closest. It is very heavy and dense. The grain resembles cocobolo, but has some very tight grain in places. Only thing is it has a very purple color to it, not brown as pictured above. Also, when it is cut, it is very aromatic. A nice perfume smell with a hint of cinnamon. Can anyone help me identify it as cocobolo or something else? Thanks.

Do you have any pics? Especially of the endgrain…

In Dalbergia, East Indian Rosewood and Kingwood are the most purple. I can’t remember the smell of Kingwood.

https://www.wood-database.com/kingwood/

Have just used some kingwood to make some pens when drilling out the barrels the smell had a hint of single malt whisky to it

That green is also reported to sometimes GLOW softly.

I work as laser cutter operator (and other jobs) at Martin Guitar. While fairly uncommon, a very small handful of East Indian Rosewood guitar backs come through on an irregular basis with a green in the lighter portions of the heart wood. An oldtimer there told me that it almost shimmers and is often turns to a somewhat lustrous silver when finished to full gloss with lacquer. Similar case with EIR that has a red color in it, often in a thin streak. On another note, freshly sanded, cut, or steam bent cocobolo does have a very strong smell. Most… Read more »

I think the East Indian Rosewood that I have seen with yellows, oranges and green is plantation grown in Indonesia, called Sonokelling. The purples and reds seem to come from India.

It could be oxygenation or a UV reactivion. Obviously, things can respond to oxygenation so that may be the culprit. Maybe freshly cut the wood and seal it as quickly as possible? Also, there could be a UV reaction going on. UV rays can fade colors or even sometimes brighten them. Brazilian Rosewood, especially when submerged under water or exposed to minerals in the soil, can develop bands of green and red that are reactive in sunlight. Check out this image:

Hi, my late father who was a true craftsman when it came to working with wood was given a gift of some Cocobolo by a friend several years ago. He used it to add decoration to Grandfather Clock cases that he made but he also made a large ‘coffee table’ with a gloss sealant over the top and turned legs. It is a really beautiful and unique piece. As we live in Ireland it was quite unusual that he had this beautiful wood to work with. Unfortunately my home is not big enough to store all the work that my… Read more »

While I can’t comment on the quality of your father’s work, Cocobolo is a very expensive wood. Around $30 USD a board foot is typical (To give you some perspective, I can buy American Beech at my local hardwood supplier for 2.95 a bf). So if you have an entire coffee table made out of Cocobolo, then the table is probably worth a few hundred dollars in wood alone. Obviously that value can be lost if the craftsmanship/design is poor. As far as the finish quality/condition, I can’t really tell you how that would effect the value of a piece… Read more »

Wow!! That is very interesting Hoover!!! Please do share how testing and actual practices goes!

Thanks,

Tanner

I am working on a project to make cocobolo wood into fine powder for the pharmaceutical industry.

there is a compound (toxic to fish and human skin) in cocobolo called OBTUSAQUINONE seems like is an alternative natural medice for poor people with cancer

Has anything new come to light since the 2013 mouse study?

i have recently been turning several items in cocobolo and have had a massive reaction to this wood it has total stripped the skin from my face and numbed most of my facial nerves it also penetrated my arms etc be very careful with this wood even though I was using face masks etc. it was not sufficient protection, this condition has lasted for two/three months and has taken a hell of a lot of clearing up, so once again please be very careful. All the best.

This applies to all true rosewoods (Dalbergia genus). Wear a mask and safety glasses when working. Shower after working with it for a few hours, as you generally should avoid sleeves in the woodshop, especially when turning. Disposable sleeves do exist and are used by some of my coworkers when working with rosewoods.

I recently purchased a beautiful bowl of Cocobolo. The grain and color is the most beautiful I have ever seen.

However: I have been warned that it will blacken over time and this really bothers me. A friend showed me a bowl he turned 15 years ago and it is so black you can hardly see the grain pattern.

Is there a finish that I can apply that will preserve the color and luster?

Not that I’maware of. The best thing I’ve found is to polish it out with micromesh, up to 12000. It’s some work, but the end result is astonishing. It looks like stone almost, but feels something like thesurface of an ipad. It will also make the wood look a bit lighter. you may not have a true cocobolo, but perhaps another very similar rosewood, which may notturn black brwn.

Dear Eric I have made a stain! This could be a really big seller! How much would you pay for natural wood-oil stain? Did I mention its water resistant? The color is bright orange-yellow and it smells great!

It takes just around 80 years for a Cocobolo tree to mature to harvest-able size.

I’m not sure how long it takes for a rosewood tree to mature to harvestable size, but I’d guess at least a few decades, if not longer; they’re very slow growers. I know some rosewood trees in Madagascar that were illegally harvested were said to be several centuries old.

As for Cocobolo oils and staining: not really practical to do that, as I’m sure there are easier and cheaper ways to obtain dye colorants.

We have a few dozen hectares of Honduran rosewood planted around 25 years ago in Guatemala. While not full size, it’s large enough to harvest. Our cocobolo is younger but I don’t think it’s a significantly slower grower than Honduran (they’re very similar and have adjoining if not overlapping territory).

I have read that Cocobolo contains color/oils that when applying a finish will bleed into other woods can this color/oil be used effectively to stain wood? Just wondering.

~Trevor

Eric how long can it take to grow one rosewood tree?

Can Burmese rosewood look similar to cocobolo?

Guatemalan Rosewood often does look like a more plain piece of cocobolo, although usually with more brown in the reds and a less tight ring structure.

Each and every board varies greatly in color and grain. You most likely got a piece of heart-wood, which from my experience is a hue of beautiful oranges, browns, greys, blacks, and even sometimes a hint of purple blue or green. very rarely any green. Sapwood boards are your darkers boards considering it’s still growing and very oily.

Hope my contributions on this page are helping,

~Tanner~

Sapwood is a light straw color.

A few days ago I bought another blank made of Cocobolo but instead of a dark piece I got a light one, can this color change? What color could this shift to?

The color generally shifts darker with UV and O? exposure.

It is usually a bright yellow when cut. Turns to apeach, then ornge, then red, then maroon, then brown, often almost black. It depends on the extracyives in the wood. highly polished, it will usually be a dark brown with black streaks, sometimes it stays a bit of a maroon.

Where does the name, Cocobolo come from and what does it mean?~Trevor

From what I’ve heard, it is coco, like coconut, meaning in the sense of exotic, tropical, and bolo, meaning stick. So, kind of exotic wood, as close as i could decipher. I heard this from a Mexican who seemed rather knowledgeable inetymology.

According to the Oxford Dictionary, it derives from the Arawak word kakabali. If so it implies the Spanish probably encountered the wood during the early colonial period as their first contact was with Taino speaking people in the Arawak group. It also suggests these people either had cocobolo on the Caribbean islands (it’s long gone now if it was ever endemic there) or obtained it through trade with mainland Central or South America. In Panama today, cocobolo refers to baldness and probably isn’t a reference to the wood but rather a tongue in check reference to coco-coconut and bolo-ball.

When any fine particles of Cocobolo hit a mucus gland, it turns into a fine acid, due to the fact of the type of oil in the wood. So when it hits your nose the fine or semi-fine particles turn into a mild acid. In the most severe cases, very fine particles from sanding that make it into your lungs produce nitric acid in your lungs, which is very lethal. I was once routing mortises into a leg made of Cocobolo and had a bunch of rough dust fly up my nose and experienced the same thing you experienced. Of… Read more »

Not being facetious, but I find it fascinating how the different flora and fauna have produced self defense mechanisms like this and others. Fascinating biology.

I am not allergic to cocobolo but one day when was making a pen from it i began to experience an awful burning sensation in both nostrils and my eyes began to water. Am i allergic to this wood? P.S. I have worked with cocobolo twice, in a well ventilated shop.

well sometimes compromise must be made. And also, Cocobolo is getting very hard to find now-a-days, so not being able to work with it might not be as bad! I encourage to try to find a new way to turn it once again without getting the painful side effects. best of luck!

~Tanner~

I’m not sure I buy the “hard to find” thing. You can go to Penn State Industries, Packard Woodworks, Craft Supply USA or any of a number of other sites and get it already cut into pen blanks and the cost isn’t any more than the other “exotic” (as compared to domestic) woods. I have turned many pens out of it and never had any issues with blisters or other nerve problems and I often wear short sleeves and never wear gloves when turning or sanding. I do wear a face shield to keep the dust and such out of… Read more »

I think it’ll only be a matter of time before Cocobolo will indeed become much harder to find, and more expensive. It’s now an endangered species, and sources seem to be drying up. Consider what Cook Woods said just last week about their stock of Mexican Cocobolo:

“This is the final shipment of Mexican Cocobolo that we will be getting. There is too much political and internal conflict in Mexico to continue buying so this is the last chance to get some!”

Well, the precaution I have taken is to simply no longer work with Cocobolo. When I was working with it I didn’t experience respiratory problems, but the skin reactions were so severe (redness that felt like sunburn, itching that might last for a week, even blistering)that it simply wasn’t worth it. Add to that my wife’s “Are you CRAZY!” whenever I dream up some new scheme that might let me turn it again! The odds are simply stacked against Cocobolo (but I still haven’t managed to part with the wood I have on hand).

Dear Tom, Actually, Cocobolo saw dust is extremely dangerous in certain cases. Irritation at the sites where dust contacted has been reported in some cases, but when sanding, take every precautionary you can, especially wearing a dust mask. I had a first hand experience with router dust and finish sander dust. When fine-sanding, the moment the dust particles enter your lungs, the fluid in your lungs causes a chemical reaction that turns the fine dust into a very potent acid and can be very lethal. i personally breathed some in when working on a table made of Cocobolo, wasn’t aware… Read more »

I do simple turning, just reel seats and pens, but I do a lot of it, and early on I wasn’t as careful about dust as I should have been. Cocobolo was my favorite wood, and I turned a lot of it. Sadly, I am now allergic to it. As far as my body is concerned, it might as well be radioactive dust! And I am not a person prone to allergies, as far as I know my allergy to Cocobolo is it, although that sensitivity has made me be very careful around any wood in the Dalbergia family. This… Read more »

I made an entire side table out of Cocobolo. The only part of the table that is not Cocobolo is the drawer box, which is naturally-stained soft maple which gives the Cocobolo a very nice contrast.

Regarding all the comments on specific gravity listed above: If you click on the link for Basic Specific Gravity at the top of the page, you’ll realize that BASIC SG is not the same as Specific gravity. (One of these days I’m going to write an article explaining how misused and useless specific gravity numbers are without a moisture content!) Anyhow, if you follow the link, you’ll get the following explanation: Typically it is based upon a wood’s oven-dry weight, (meaning a moisture content of 0%, which is the lightest the wood can ever get), and its green volume, that… Read more »

Hi,do you think that BASIC Specific Gravity = Specific Gravity?,and

that Specific Gravity = Weight?or if the green lumber = dried lumber?please let me know what happen?.Some literature say Cocobolo Specific Gravity is 1.1 for that sinks in water.

@ Jim: Specific gravity is definitely wrong.

If you look at the average dried weight: 1,070 kg/m3, converting to units of g per cubic cm gives you a specific gravity of 1.07, which would sink in water.

Specific gravity wrong. Must be greater than 1 to sink in water.

I made some handles for kitchen knives from cocobolo back about 1970. No finish of any kind was placed on them. They are fine today in spite of almost daily use and daily washing. One of them shows a slight crack, however.